And the chips do break

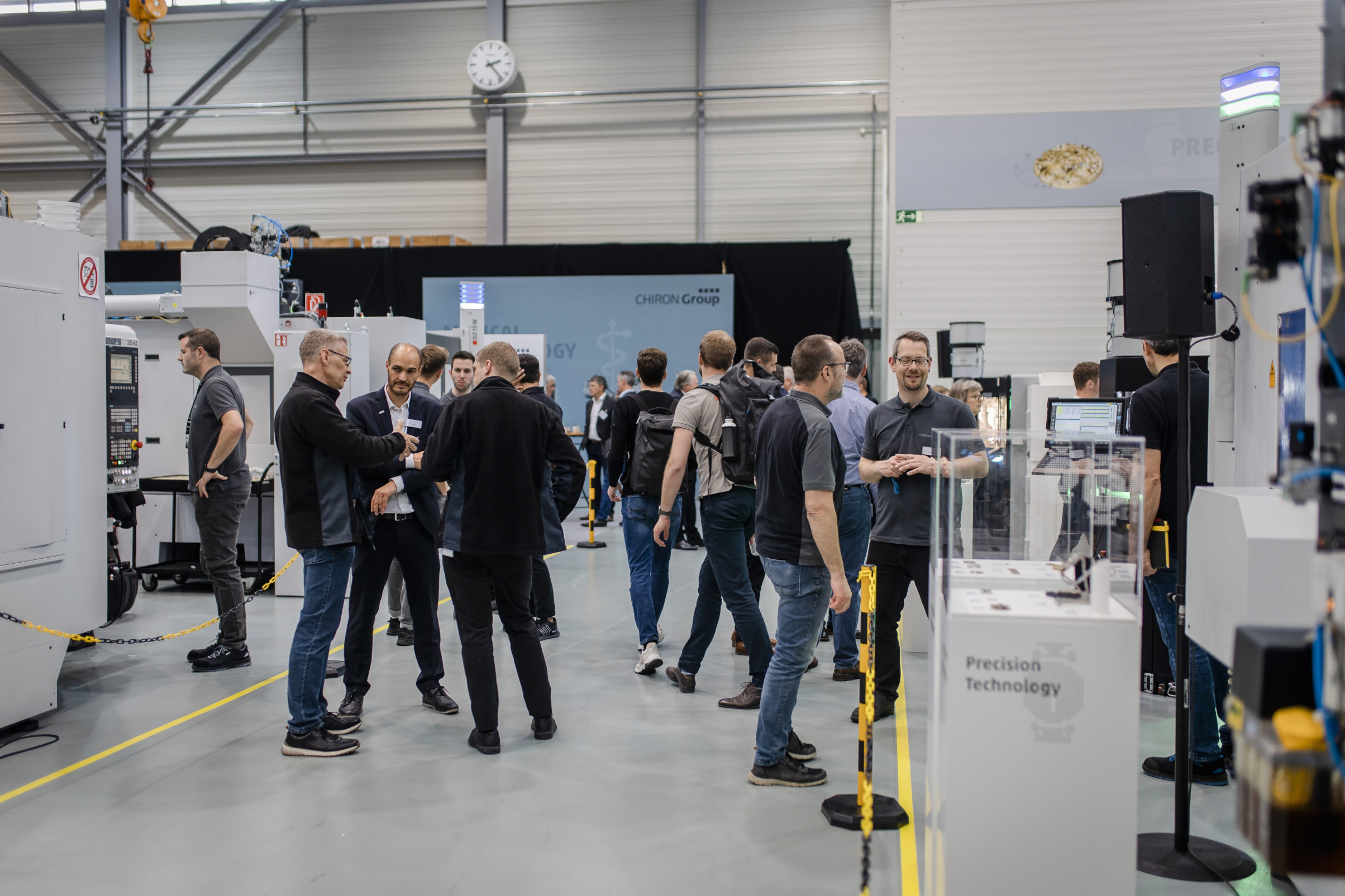

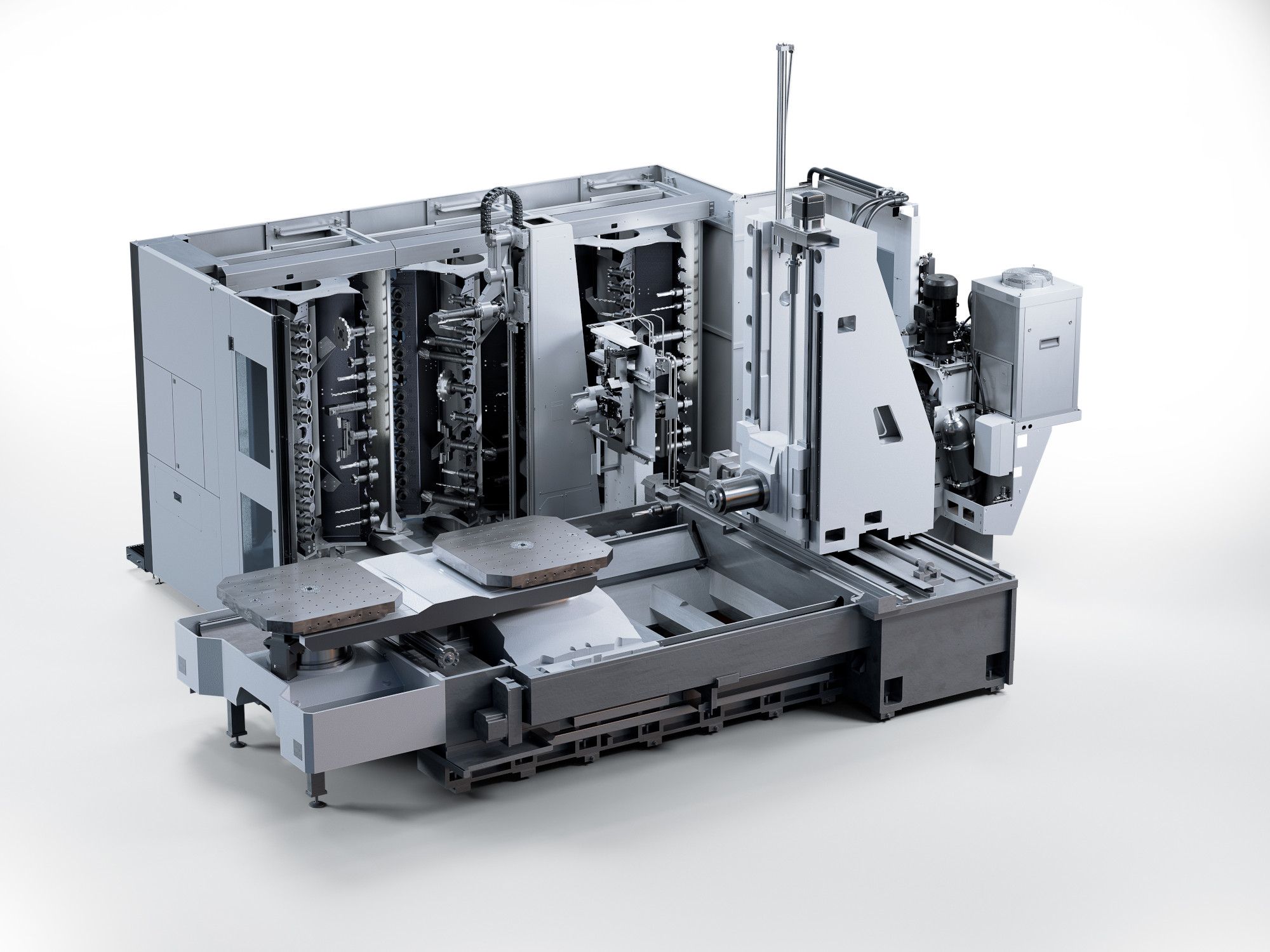

International regulations limit the amount of lead in copper alloys. This is good for health and the environment, but it confronts manufacturers and machinists with major - or perhaps better said, long-term - challenges. Without lead in the alloy, long chips often form. The tool specialists at ISCAR have teamed up with experts from the Wieland Group to tackle this issue. At the TechCenter in Ettlingen, they have jointly developed a wide range of drills, milling cutters, turning tools, and grooving tools that can be used to machine lead-free brass with ease.

Founded in 1820 as a bell foundry in Ulm, the Wieland Group is now an international supplier of copper alloys, semi-finished copper products, and component and system solutions. With a global network of more than 80 production sites, service and trading companies, and around 10,000 employees, the company offers a broad portfolio of products, technologies, and services. From prototypes to series production, Wieland develops solutions for the automotive, aerospace, electronics, refrigeration, and air conditioning industries, among others. REACH Annex 17, RoHS, DWD, and ELV – numerous international regulations limit the lead content in copper alloys. This means that materials that…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen