Chip control and μ-precision

Später lesen

CUTTING TOOLS

Von

Maxime Mader

veröffentlicht am

29/08/2025

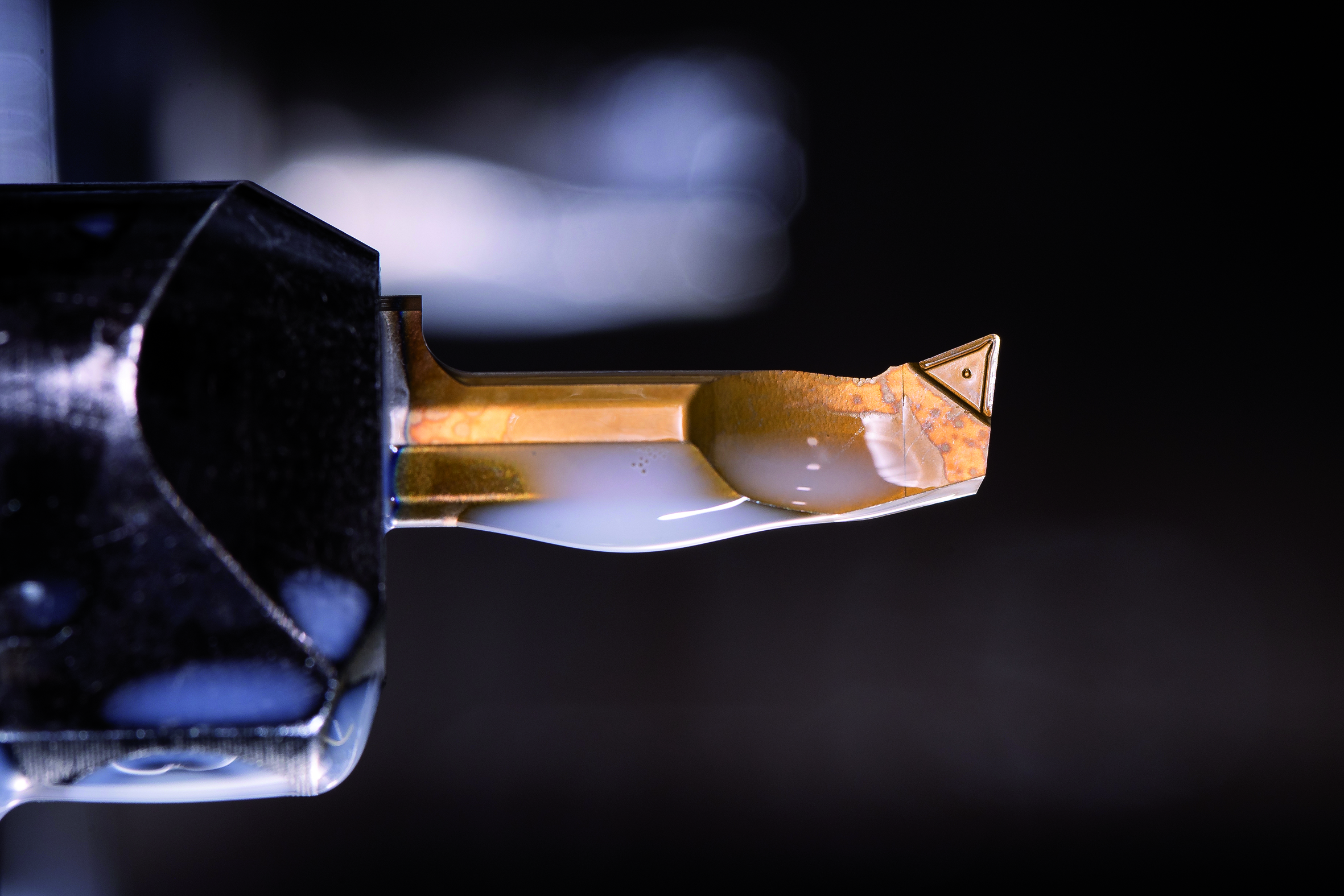

For over 40 years, the brothers Wolfang and Gottfried Rich have relied on precision tools from Paul Horn GmbH. As both a customer and supplier of Horn, RICH Praezision GmbH produces high-quality turned parts for various industries. For boring, the company relies on the new generation of Horn Superminis with sintered chip breaking geometry. “With the new inserts, all chip problems during boring have virtually disappeared into thin air,” says Gottfried Rich. The new tool is used for boring the body of the Horn SX interface.

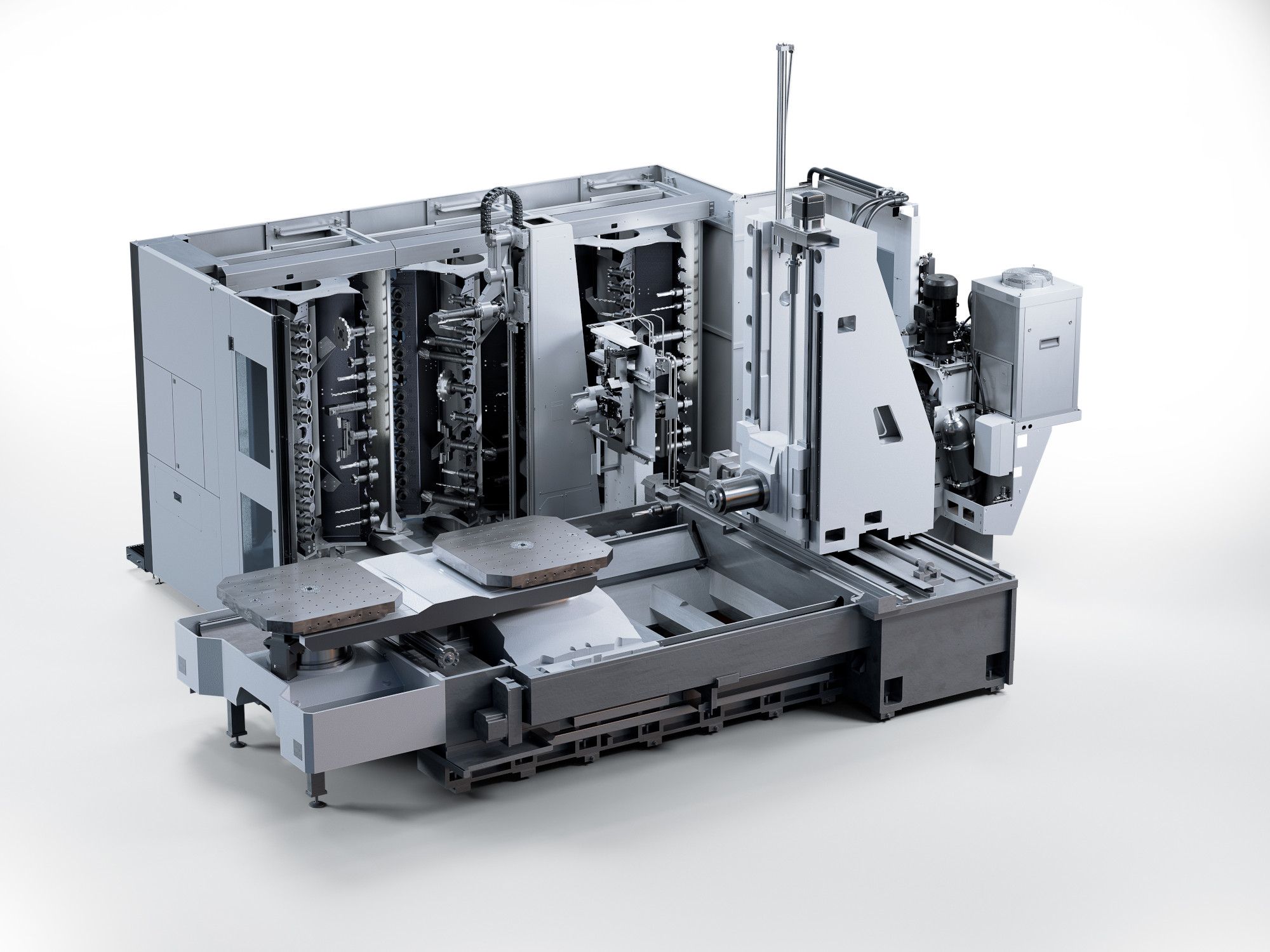

RICH Praezision GmbH has been a supplier to Horn for several years. The company produces the body of the precision interface for the Horn tool system SX, which is a further development of the 42X type family. The cutter head is connected to the contact surface of the tool body via a stable, robust, yet highly precise thread. This interface offers several advantages: high stability due to the generous thread size, wide support due to the large contact surface and precise changeover accuracy in the µ range, which is always in the centre of the tolerance band. In addition, changing…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen

PAUL HORN GMBH

www.horn-group.com

Über uns zerspanen

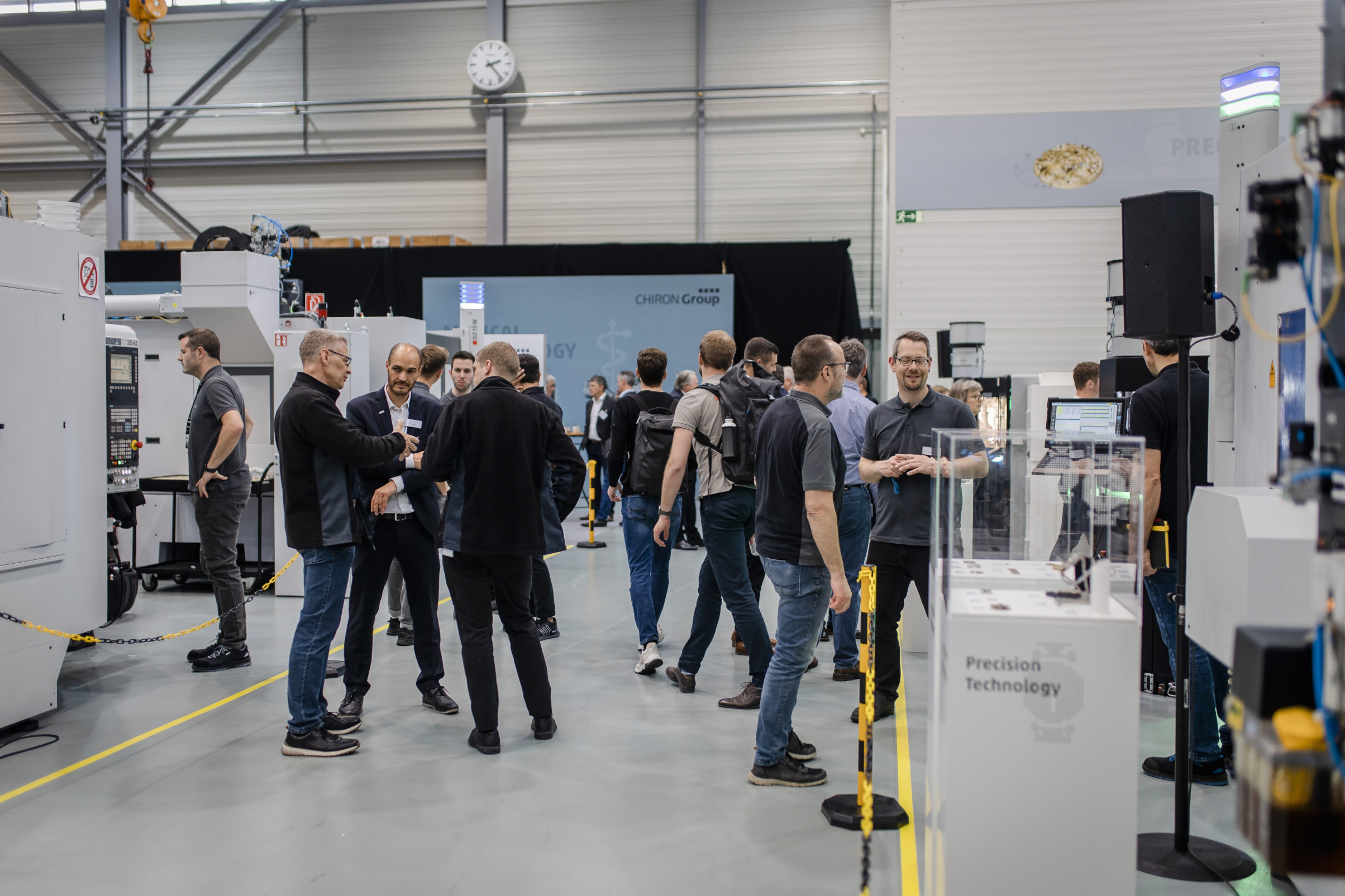

HEDELIUS MASCHINENFABRIK GMBH

Zukunftsweisende Fertigungskonzepte diskutieren

CUTTING TOOLS

actualites

Meistgelesen

Lesen Sie auch

3D3D-Druck5-Achs-Schleifmaschinen5-AchsenAdditive Manufacturing

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Experten präsentieren effiziente Fertigung

Automation

actualites