Digital Machining Market Place – DiMaP goes hybrid

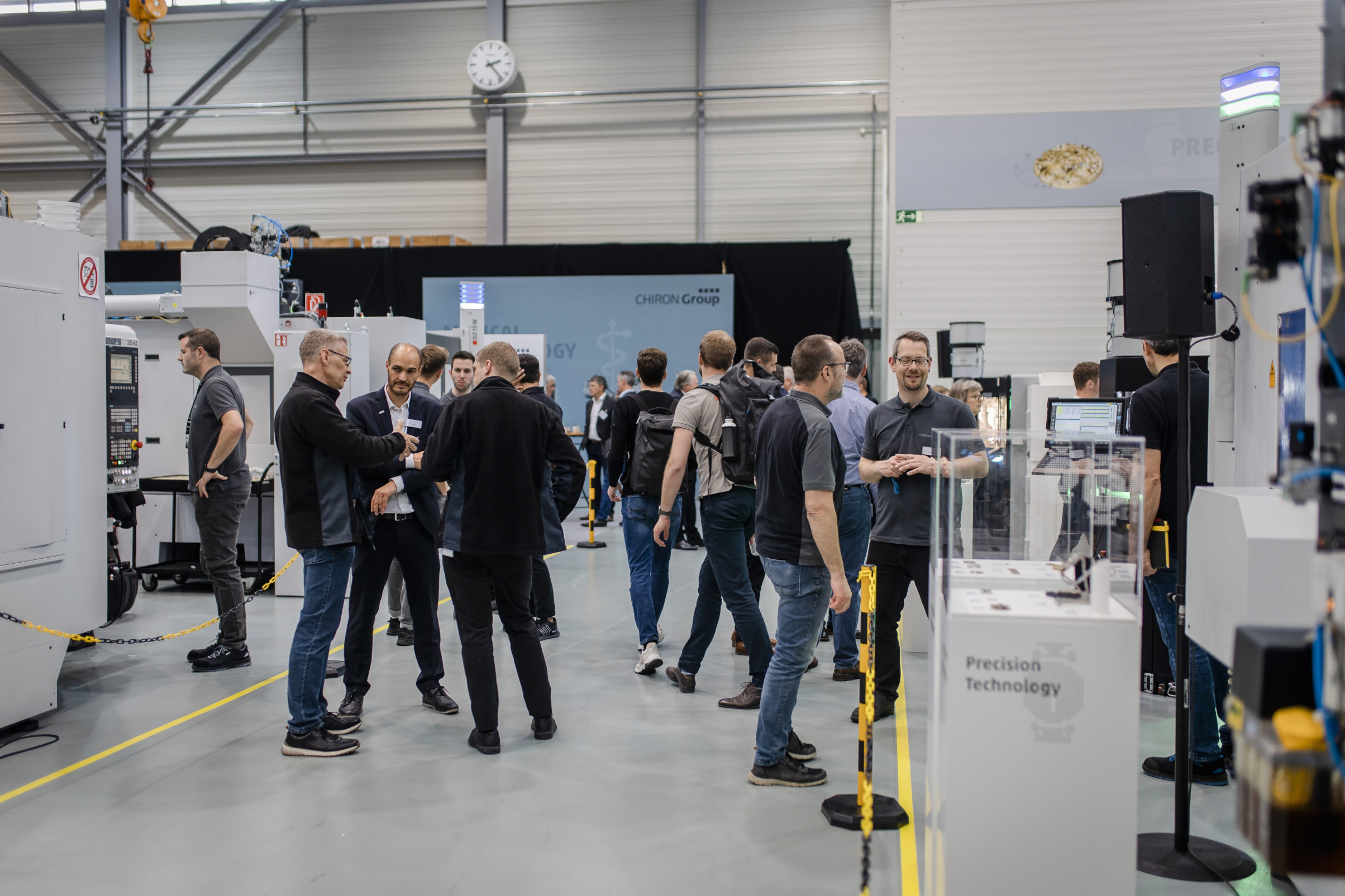

DiMaP 3.0 from 21st-24th of September 2021 - How the machining industry turns DiMaP into a format that combines the physical trade show with a digital event.

When the wireless sensor systems company pro-micron GmbH from Kaufbeuren initiated the first DiMaP conference in March 2020, the motivation was purely to compensate for the lack of trade show opportunities during the Corona phase. What was first intended to be a presentation vehicle for companies offering digital machining solutions, quickly turned into something much larger, much more strategic and most importantly, something driven in a spirit of close cooperation along the machining value chain. After the kick off DiMaP in July 2020, DiMaP 2.0 followed in March 2021 in a larger and even more professional format.

The DiMaP 2.0 already involved 16 companies and institutes presenting digital machining examples to more than 1.000 participants with 4.448 online

seminar registrations in 3 languages – German, English and Chinese. Participating DiMaP2.0 members where pro-micron, DMGMORI, Hermes, Ceratizit, Hufschmied, Urma, Regofix, Fooke, Blaser, Tvarit, Heule, Liquid Tools, and the machining institutes PTW Darmstadt and the Fraunhofer institutes IPA Stuttgart, IWU Chemnitz and IPT Aachen.

All DiMaP 2.0 exhibitors jointly marketed the 4-day conference, which was kicked off by a welcome speech by Dorothee Bär, the minister for digitisation within the German Government and Dr. Eberhard Sasse, head of the Sasse Group and President of the Bavarian Chamber of Commerce Organisations.

A digital group photo provided a personal touch during the online marketplace.

“The presentation formats for us as an industry are currently developing faster than ever before – hybrid is almost standard, but cooperation in the interests of users is also the topic of the hour. In such a practical and application-oriented exchange of experiences along the entire value chain, added value for the user can then be very easily presented”, stated Michael Blank, Director Marketing & Communication der CERATIZIT Group

All DiMaP 2.0 partners introduced their companies at their virtual DiMaP booths, handing over the baton to the next fellow exhibitor.

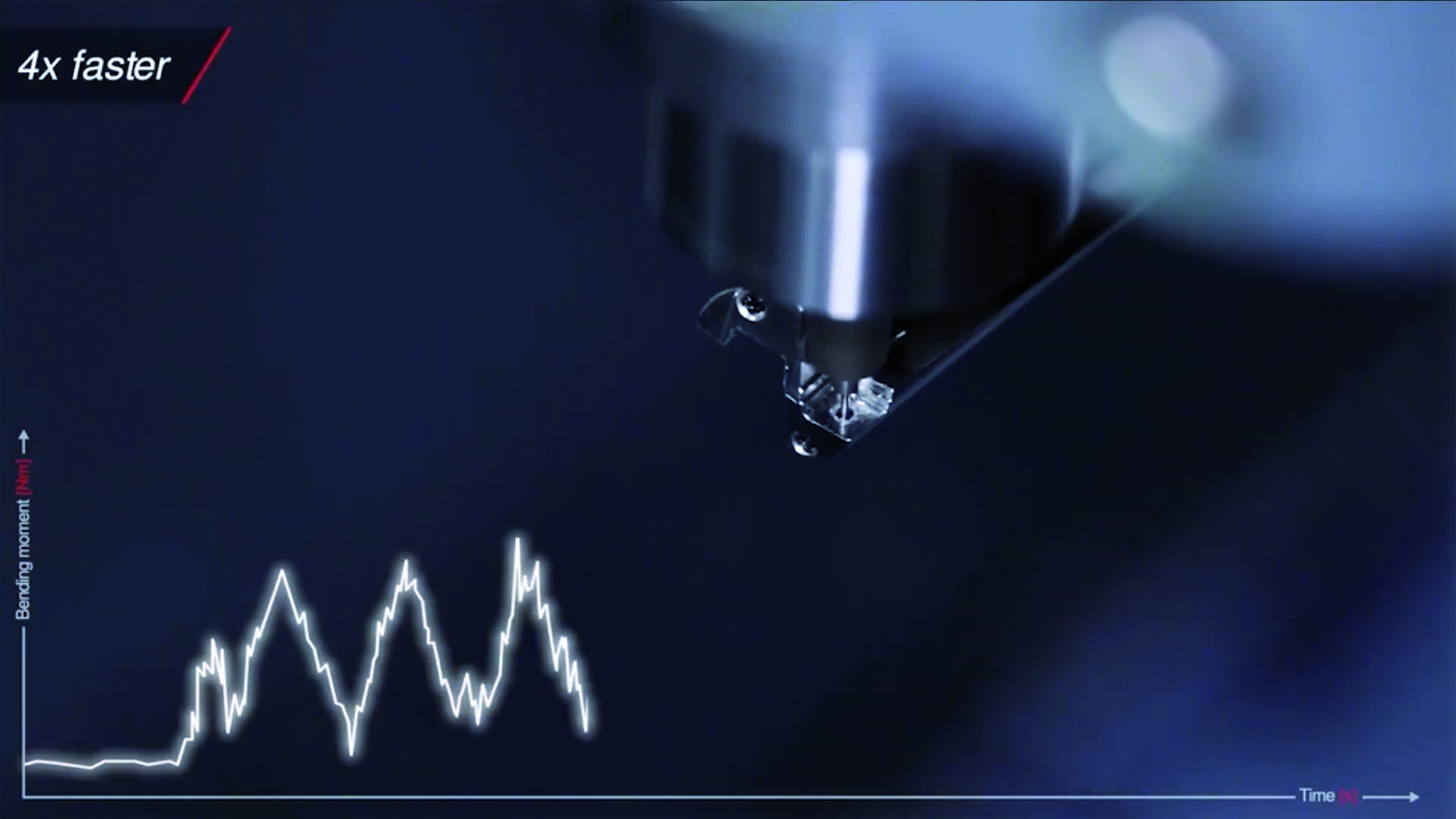

Having created a spirit of togetherness, the kick-off event was followed by fascinating online seminars on the subject of digital machining. A wide subject range from smart coolant management, from big data to smart data with spike or AI compatible data generation was presented from the companies studios as well as live out of the machine. Interestingly presenters and listeners are gaining increasing experience in turning a one-way presentation into a dialog, by using survey tools such as slido to ask the audience questions such as: who amongst you has experienced prematurely failing tools or sporadic materials faults?

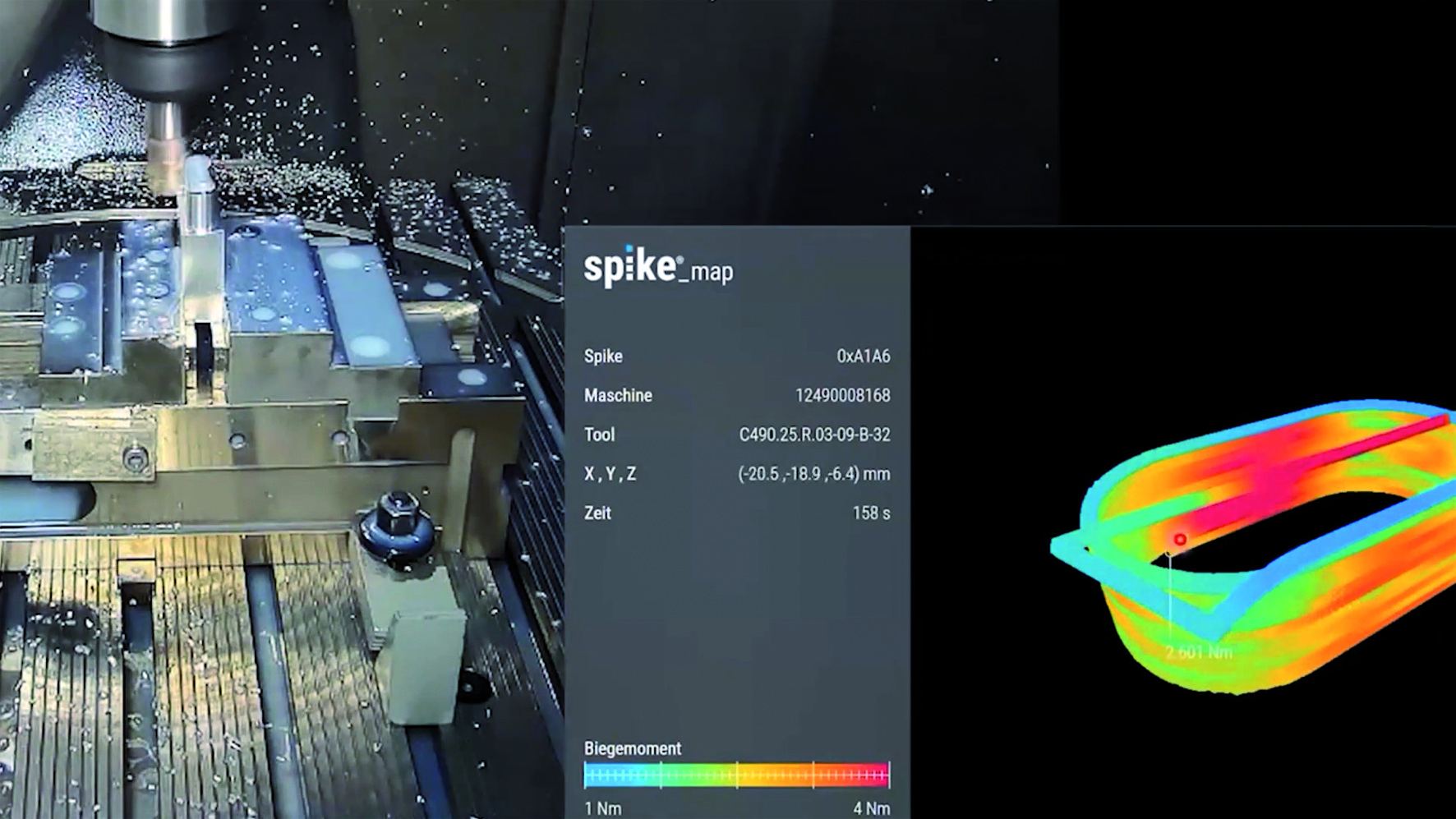

With the real digital twin of the spike_map per

workpiece, surface quality and dimensional

accuracy are checked in the process.

Listeners could thus be turned into a communicating party, exchanging views and benefitting from other participants` experience. Participants are increasingly asking questions via the chat function and moderators where able to respond spontaneously. Switching from presentation mode straight into the live machining process and back increased the real live experience. Cameras installed inside the machine enabled every listener to have an extremely close up view into the machining room or the HMI.

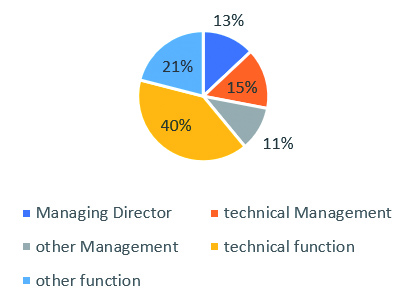

Up to 120 participants and on average 74 participants per seminar registered. Interesting was also that the DiMaP attracted all organisational levels within companies as the following pie chart illustrates.

During DiMaP the exhibitors where available for a personal exchange at their individual DiMaP booths. Interestingly some exhibitors experienced more significant booth traffic than others.

The DiMaP 2.0 helped to answer technical questions on an operational machining level, but also gave an outlook on what institutes and companies are working on to create future solutions.

More information about the individual DiMaP 2.0 program can be found on the DiMaP website www.digital-machining.de, which also announces the DiMaP 3.0,

to be held as a pre-EMO Event from the 21st – 24th of September 2021.

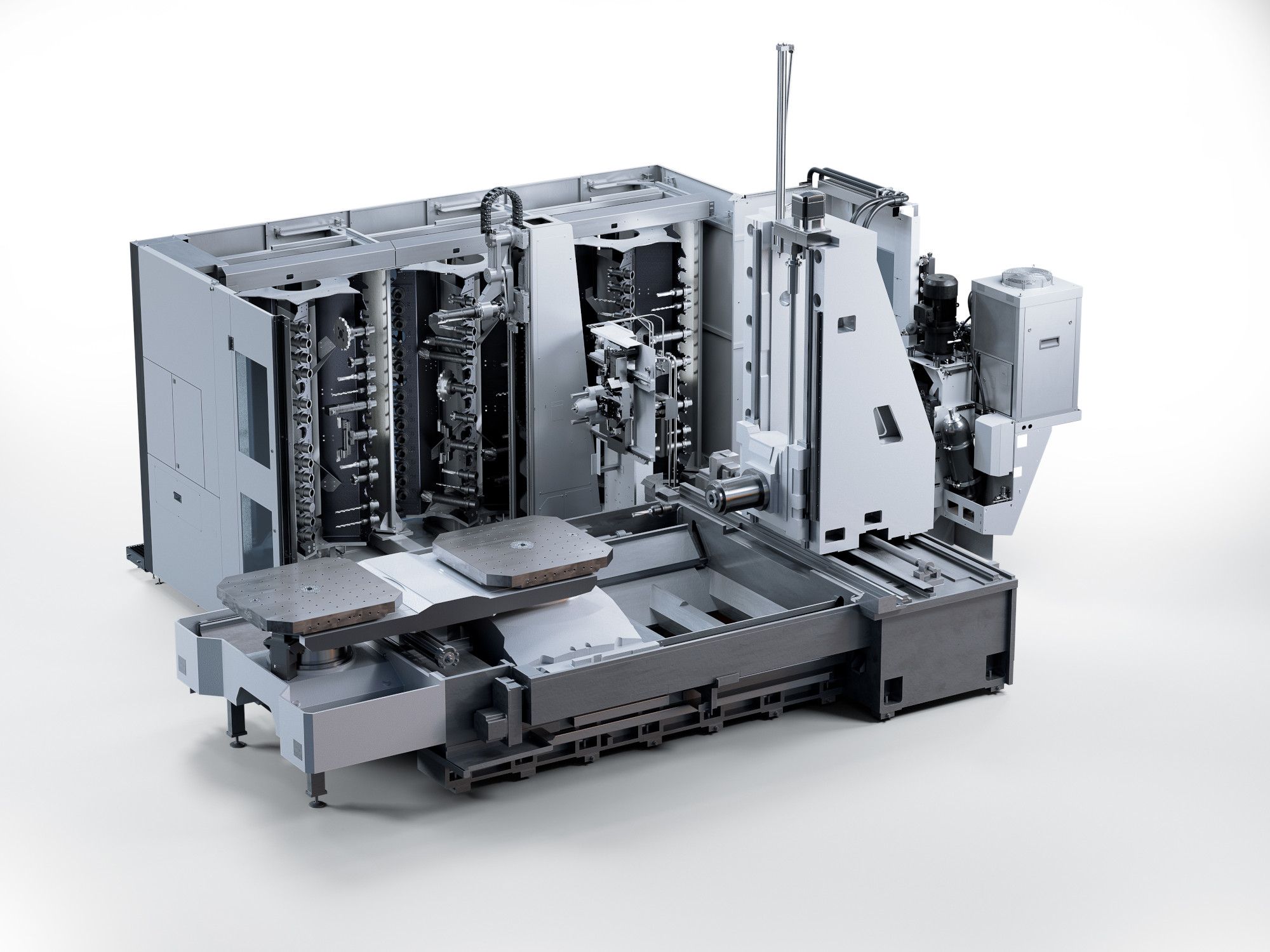

„DiMaP is an opportunity to grow together as a value chain, to integrate individual offerings and present them as well coordinated, easy to implement as manageable solutions”, says Managing Director of DMGMORI subsidiary Deckel Maho in Pfronten.

The highlight of DiMaP 2.0, was an outlook into the future: How digital will machining be in 5 years time really? For the first time, the so-called Directors` Exchange took place in the newly built DiMaP studio, in which the management board of leading companies in the machining industry discussed in a small group. In a live transmission via YouTube, 191 DiMaP visitors were able to experience at first hand, how the machining value chain jointly discussed further developments. This exciting and unique set-up consisted of Robin Berger (Works Manager Wertach Alois Berger Group), Alfred Geißler (Managing Director Lid Maho Pfronten GmbH), Rudolf Meyer (Managing Director Liquid Tools), Wolfgang Sochor (COO and member of the Hawe Hydraulik SE Management Board), Thierry Wolter (member of the board of the Ceratizit Group) and Hubertus von Zastrow (managing partner of pro-micron GmbH). The discussion was prominently moderated by the co-head of the Fraunhofer IPT Institute Aachen, Prof. Dr. Thomas Bergs, who started the sometimes-controversial exchange with an opening presentation. The conclusion: the digitisation in the machining industry will come – if we take the employees of the industry with us during this change, it can become a major competitive advantage for Germany and Europe.

Ceratizit: micro thread milling in combination

with Toolscope and spike for process

integrated 100% quality control.

The very enriching, entertaining and varied input and exchange during the online seminars and the Directors` Exchange brought an exciting fair feeling to the machining-fans. On the last day of the online marketplace the visitors came together for a virtual after-DiMaP beer to celebrate. Each participant was sent a DiMaP beer with a special label – the logos of all participating companies and institutes – which enabled not only another exciting exchange (this time in a more relaxed atmosphere), but also a toast together. It’s hard to believe: 77 machining specialists discussed the future of machining on Friday afternoon, supported by the moderation of Silke Greiff (Marketing Officer at pro-micron GmbH) and Christopher Prätzas (Business Development at Tvarit GmbH). The discussion was so exciting, that 1.5 hours passed by on the fly as an amazing finish.

The next Beer will be opened soon after the next DiMaP – the DiMaP 3.0, which will take place in September – October 2021 – for the first time in a hybrid format. At the beginning the exhibitors will present themselves and their new developments online. The focus of the presentation are specific use cases in digital machining. For example, pro-micron and DMG, Ceratizit, big data manufacturing or Regofix, Blaser or Gemineers will in small groups jointly present their coordinated solutions. With cameras positioned directly in the machine, visitors can see the inner workings of the machines as close as the machine operator does.

DiMaP 2.0 addressed all organizational levels

Visitors of the EMO can use the pre-Emo DiMaP 3.0 as a navigation for the topic of digital machining, because after the online Kick-off, the DiMaP will be on site at the EMO Milan 2021 in the so-called DiMaP 3.0 Trail. Visitors can follow the DiMaP trail by going to the individual DiMaP 3.0 members´ booths and discuss the use cases shown in advance with the experts at the EMO. And so it is no wonder that leading trade fair organizers have already contacted the DiMaP organization team to discuss specific types of cooperation between DiMaP and the physical trade fairs.

You can achieve a lot on your own … but with DiMaP – the amalgamation of various partners in the machining value chain – can achieve even more: The focus on digital machining means that specific solutions can also be created as a large community. The success of DiMaP arises from a common interest and the joint goal. Colleagues from machining get to know each other through regular exchange during the concept development, they contribute a wide variety of ideas and solutions and thus ensure a unique joint marketplace.

„DiMaP is new for all of us, but thanks to the community and cooperation that’s been created, it has already become indispensable.“ – Hubertus von Zastrow, DiMaP initiator and managing partner of pro-micron GmbH. Significantly more extensive DiMaP services are already being discussed in the DiMaP executive committee, for the future. Let’s see what comes next…

Backstage at the “virtual” booth from pro-micron.

DiMaP 3.0 in September – with the new concept of a hybrid trade fair.