Grinding technology for the low-emission mobility of the future

Später lesen

Focus

Von

Maxime Mader

veröffentlicht am

26/08/2024

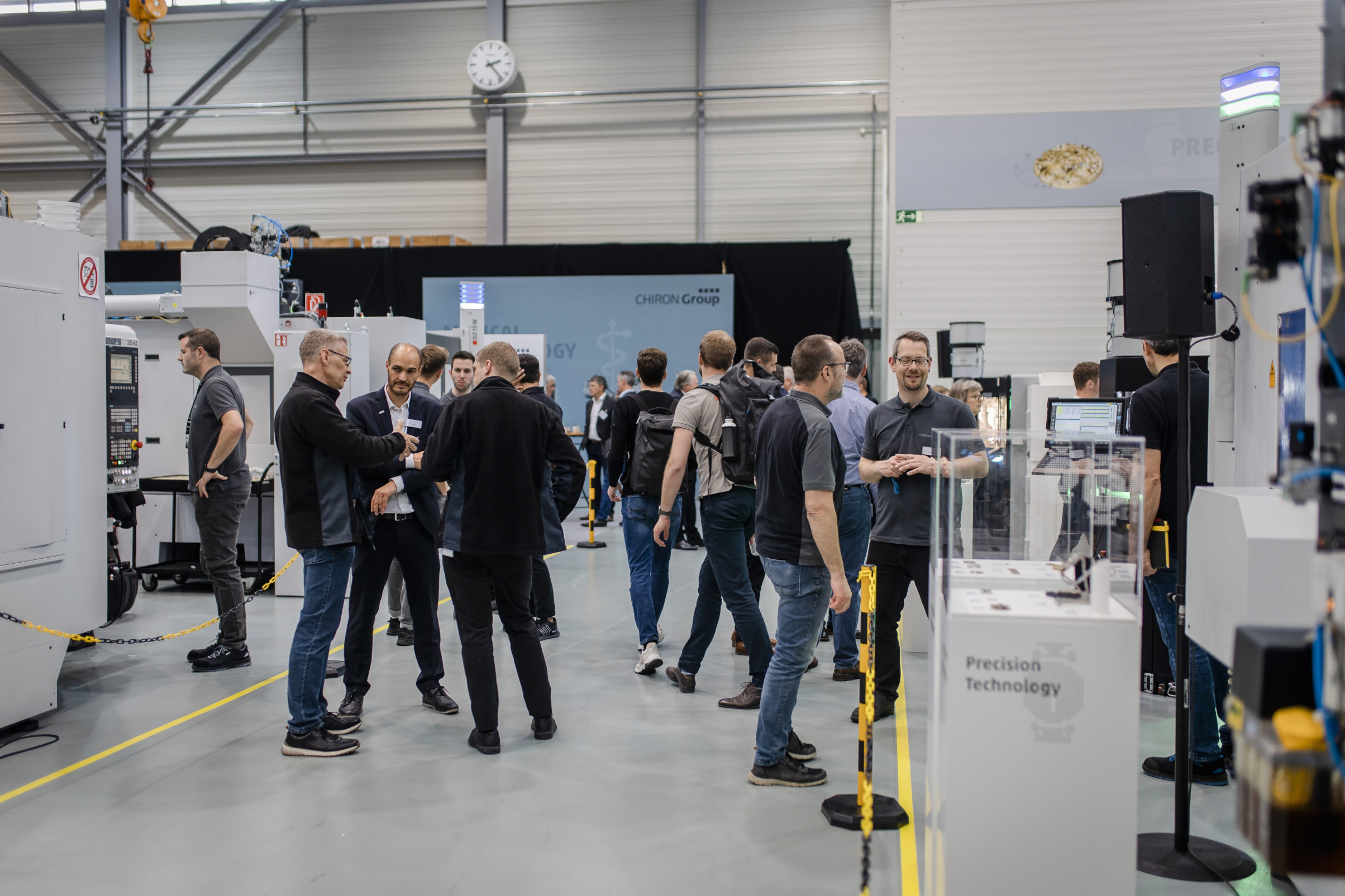

Grinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or brake discs with reduced fine dust and hard coatings that are difficult to machine. EMAG presented what solutions for these processing tasks look like at the Grinding Hub 2024 in Stuttgart.

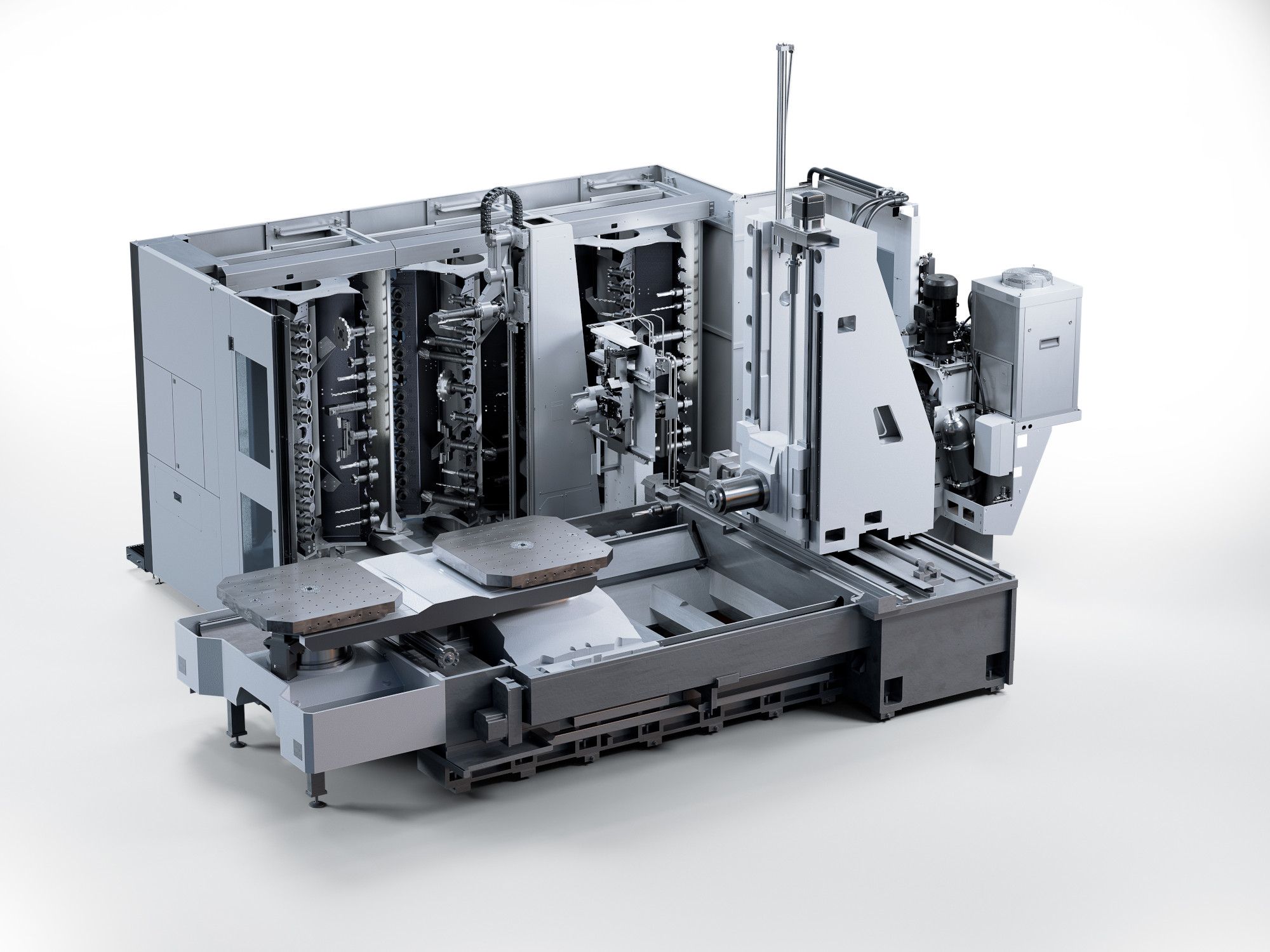

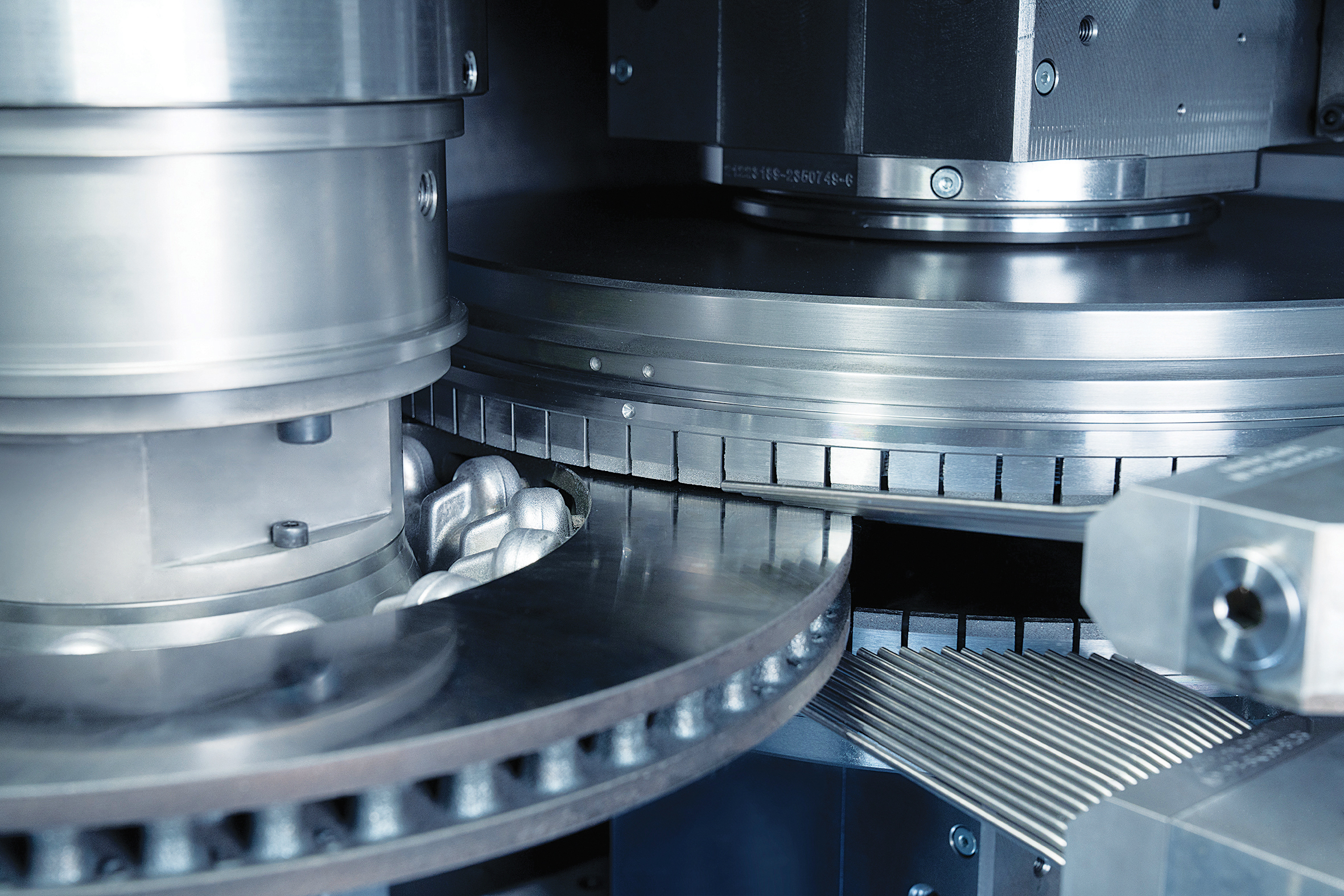

The VLC 450 DG brake disk grinding machine In March 2024, the European Parliament adopted the EURO 7 standard. For the first time, it sets limit values for brake particle emissions for cars and light trucks. Irrespective of the drive system used, a switch to new brake technology is necessary. The most promising approach to reducing particulate matter in the braking system is currently the use of hard-coated brake discs. The friction layer consists of a soft matrix with carbides, e.g. titanium carbide. Due to the fundamentally different cutting behavior of the two materials, the design and development of suitable grinding tools…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen

EMAG GmbH & Co. KG

http://www.emag.com

Über uns rubriken

Meistgelesen

Lesen Sie auch

3D3D-Druck5-Achs-Schleifmaschinen5-AchsenAdditive Manufacturing

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Experten präsentieren effiziente Fertigung

Automation

actualites