Inspiration for successful machining

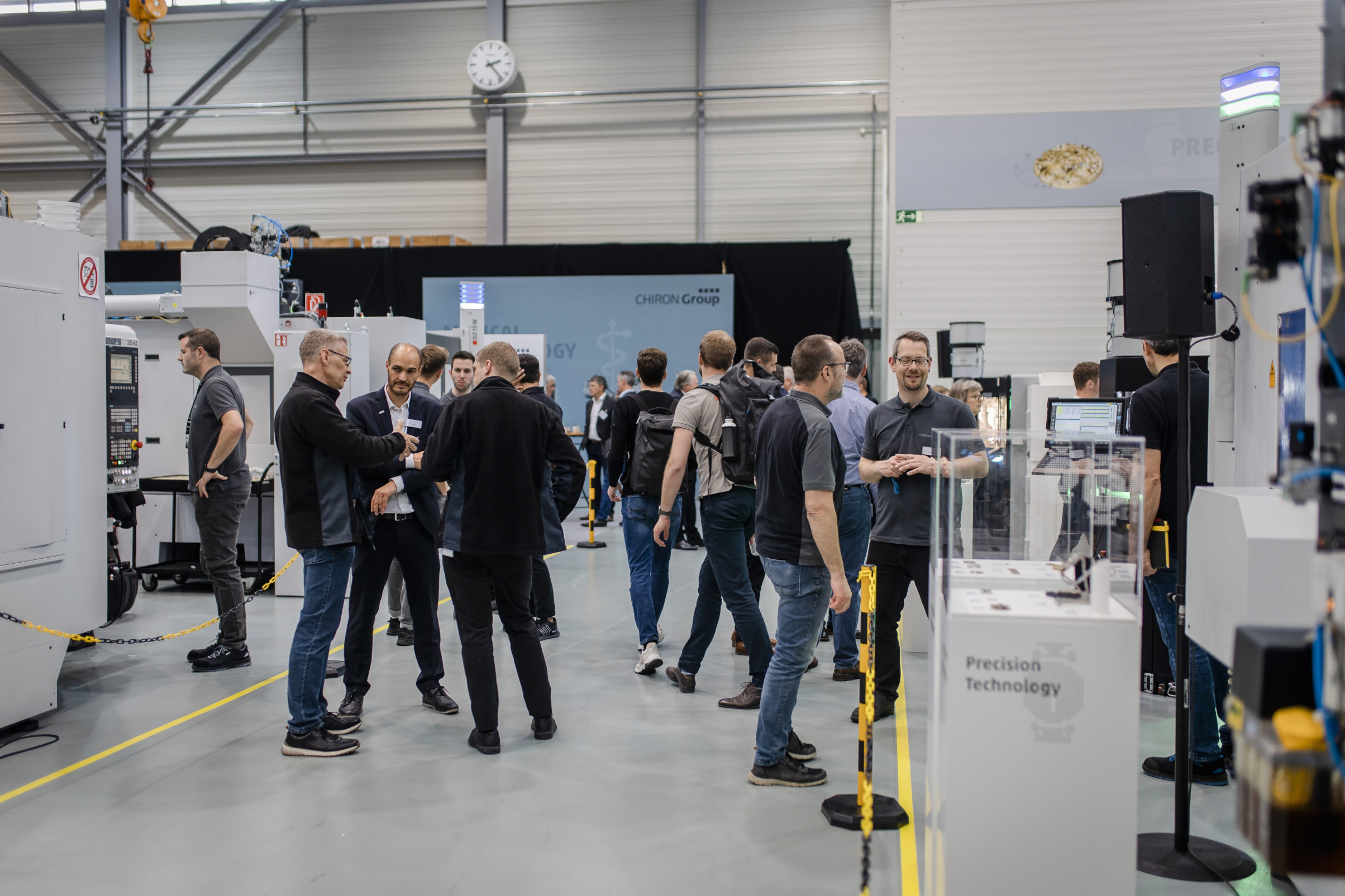

Do you expect events to feature the same things every year? No! Each year, there’s a multitude of new highlights to explore at the INDEX Open House: machine innovations live and in action, automation solutions with a wide array of options, and the latest developments in the digital INDEX iXworld. There was also plenty of opportunities to exchange views with machining and industry experts.

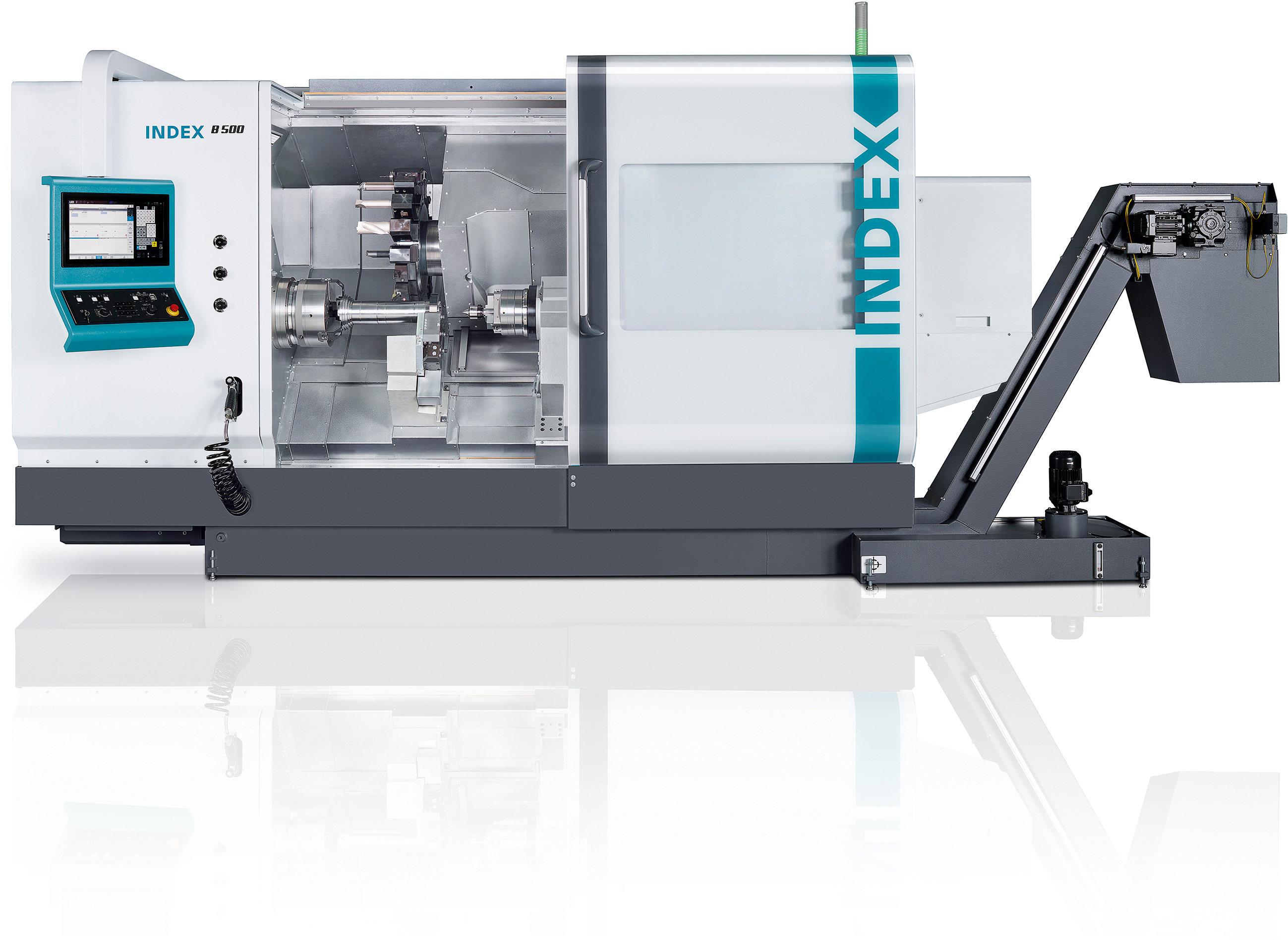

From April 25 th to 28 th, 2023, it was that time again for the INDEX Open House 2023 in Reichenbach/Fils, where INDEX presented innovative machine solutions and services relating to the machining process chain. Highlights definitely include the INDEX B500 universal lathe, which now provides even more machining options in a new long version with a turning length of up to 1200 mm. INDEX can optionally equip this machine with an 18-station radial turret.

An unsurpassed classic to this day is the INDEX ABC CNC automatic lathe, known for its performance density and dynamic response. The new version – now also available with FANUC controller – has an Y axis as standard. This machine stands out with its upper turret, which in addition to Y functionality, offers an electronic indexing axis, height adjustment, and the ability to fit twin tool holders.

Compact, precise, fast

There are also innovations in the sliding headstock automatic lathes. Based on the TRAUB TNL20, INDEX has developed the TRAUB TNL32 compact, which offers the small footprint of the TNL20 with a bar clearance of 32 mm. Like all other TRAUB TNL machines, the “compact” 32-mm variant enables extremely productive sliding and fixed headstock turning for workpieces of medium and high complexity.

This is also true of the TRAUB TNL12 sliding headstock automatic lathe, which has been packed with new features since 2022. Like its larger siblings, it can now be easily converted to a fixed headstock lathe. It is also more compact and has better kinematics than its predecessor.

TRAUB TNX220.

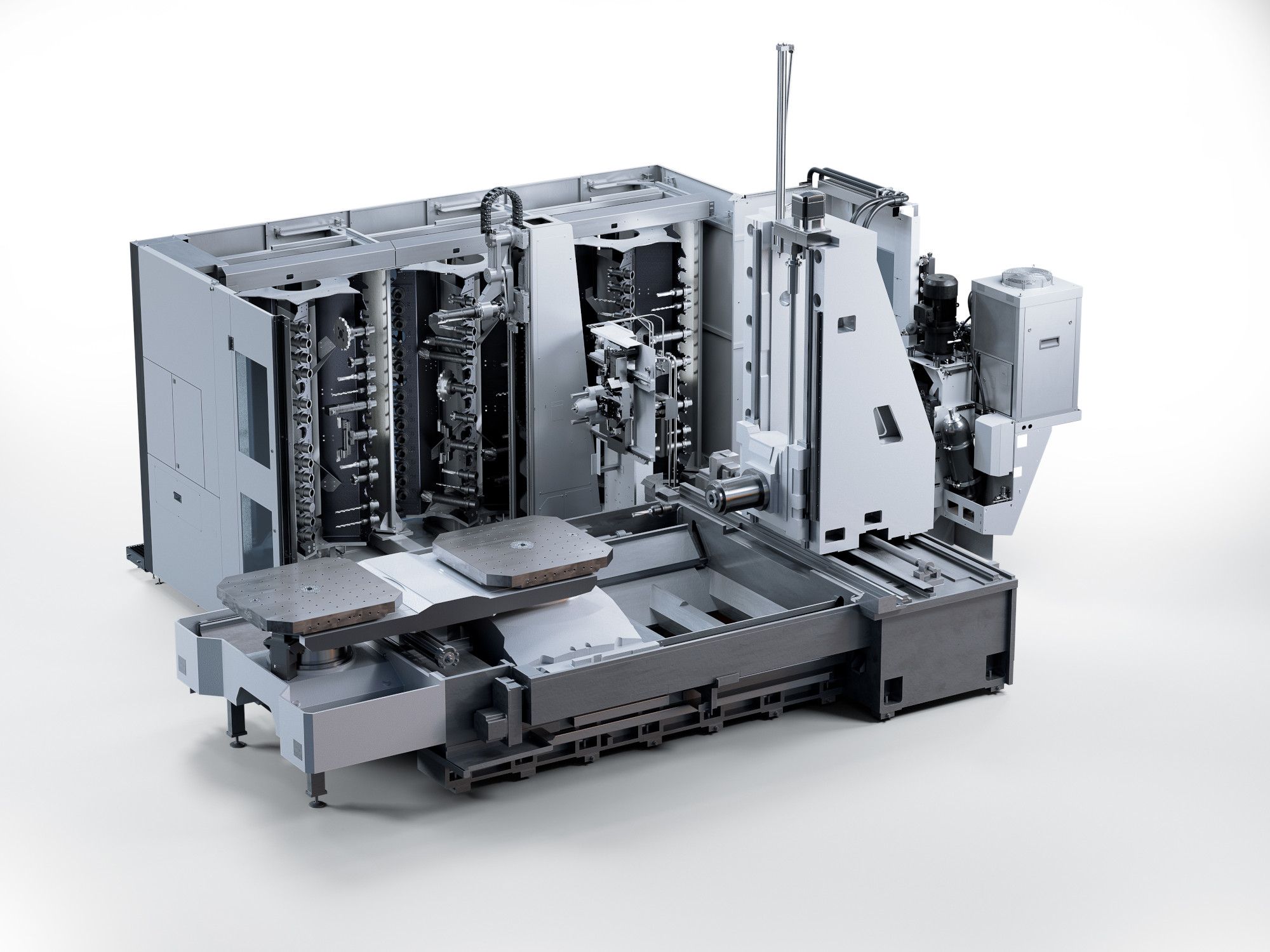

A broad range: turn-mill centers for productive, complete machining

INDEX turn-mill centers which were presented in four different sizes and automation levels at the Open House, and they was all fully in tune with the times. They include the TRAUB TNX220 turn-mill center, the successor to the successful TRAUB TNX65 milling spindle version. Now with 76 mm spindle clearance, 200 mm chuck diameter, and a considerably increased turning length of 900 mm, the entirely redesigned turn-mill center gains a significant performance boost. At the Open House, the TNX220 model on display will feature iXcenter L automation. This consists of a robot cell placed in front of the machine, to which various modules can be docked from two sides: for example, with pallet/rack modules, equipment for deburring, cleaning, or laser marking, or a measuring/testing station. With this measuring cell, INDEX will be demonstrating its Closed Loop solution for autonomous production. The best part is that INDEX supplies the entire system from a single source – from the lathe to the iXcenter robot cell to the test equipment, and all the way down to the Closed Loop interface.

Open House attendees was also the chance to see the INDEX G220 turn-mill center with the INDEX MBL76 bar loading magazine tailored to match the new machine design and turning spindle diameter. The INDEX G320 was shown with the new iXtools additional tool magazine, which offers up to 392 tool locations and allows the powerful milling spindle to make full use of its abilities. The range also includes the larger INDEX G420 and INDEX G520 turn-mill centers. The latter was shown as a long version for the first time.

INDEX B500 in the long version.

When you need more spindles

Anyone who wanted to experience highly economical turning operations could definitely not miss the presentation of the INDEX MS24-6 CNC multi-spindle automatic lathe. Compared to its MS22-6 predecessor, it has a slightly larger maximum bar diameter but remains compact and provides numerous features. Given decreasing batch sizes, the optimized setup concept is increasingly important. An essential element is the INDEX quick clamping system with integrated W-serration on the cross slide.

The INDEX MS22-8 multi-spindle machine also demonstrates virtually limitless machining flexibility. With its eight main spindles and up to two swivelling synchronized spindles, it enables the use of up to 16 tool carriers. It can be used for eight-spindle machining with simultaneous rear-end machining. For simpler parts, however, it can also be used as a double four-spindle machine, opening up the ability to further reduce cycle times by simultaneously producing two workpieces.

MEET THE EXPERTS – INDEX expertise for top user benefits

As an extra to the presentation of the INDEX and TRAUB machines – as well as booths featuring 30 partner companies – INDEX is inviting all visitors to increase their knowledge of important technological subjects. Guests participated in lectures and discussions with experts from the fields of gear cutting, whirling, and grinding, as well as automation, procurement, refit, and industry management.

Digitization and iXworld continue to be of great importance. The key element is the INDEX iX4.0 IoT platform with its numerous iX4.0 apps. It ensures transparency and productivity in the entire machining process chain. At the Open House, the INDEX digitization experts was also demonstrated how efficiently and easily the iXshop can be used for the procurement of spare parts and other tools and what advantages iXservices promise in aftersales service.

INDEX ABC with Fanuc.