New technologies for carbide milling

Up until now, the production of pressing tools - dies and punches for the pressing of indexable inserts - was a multi-stage process at Boehlerit that required work on several different machines. Contenu de l'article:

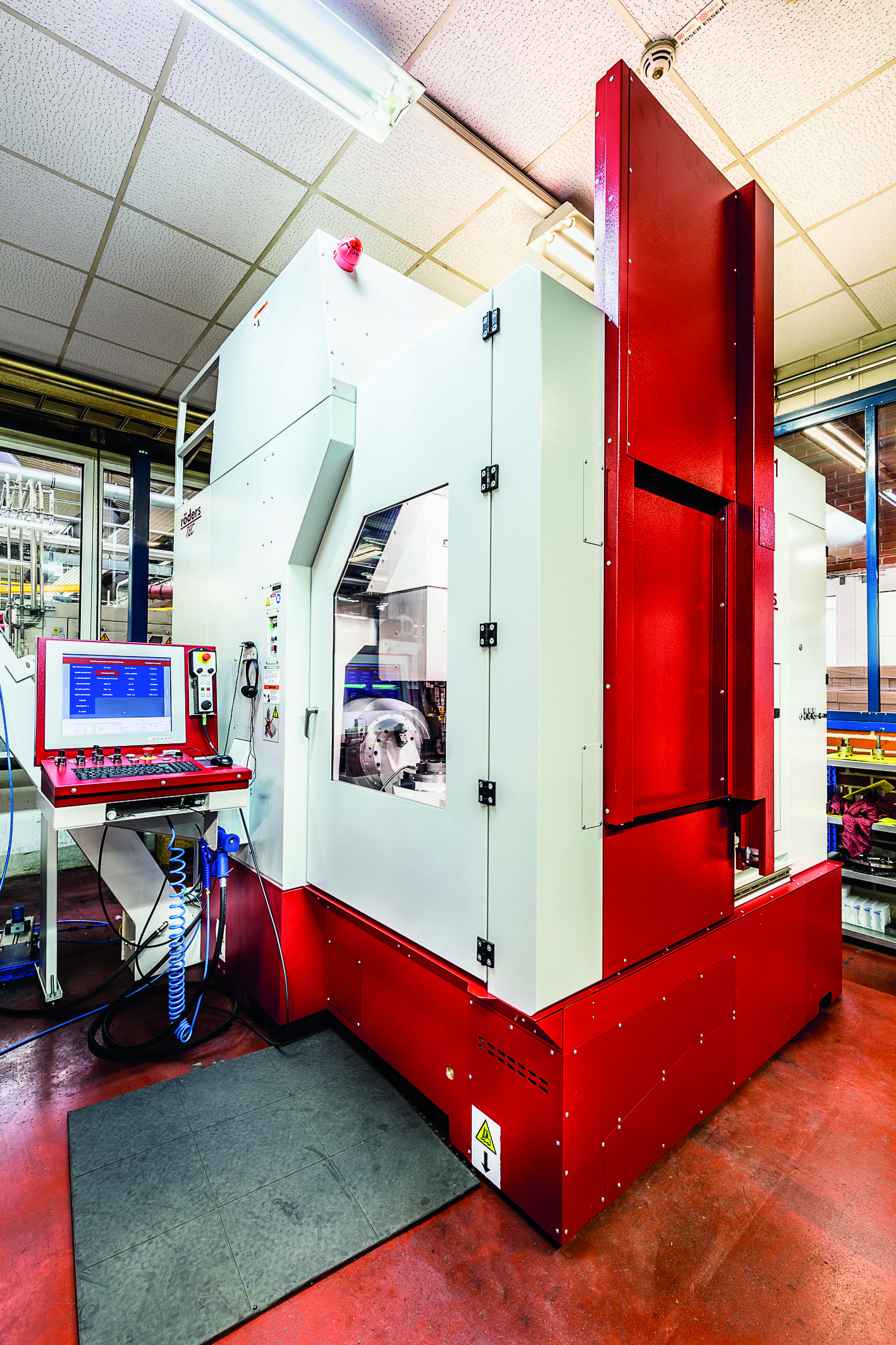

The individual manufacturing steps included coordinate grinding, electrode milling and die sinking, all before the laborious manual polishing, the final step. “The option of milling carbide pressing tools hasn’t been around very long, as diamond milling tools for these sort of applications simply didn’t exist on the market”, explains Martin Willinger. “Boehlerit wanted to utilise this technology, with the goal of completing milling and grinding operations directly on a single machine.” The company has now put this plan into action with the new precision 5-axes milling machine Röders RXP601 DSH, which comes with state-of-the-art linear drive technology and an innovative package for coordinate grinding. Dies may now be ground around their circumference and the face geometry may be milled directly on the carbide, using diamond-coated milling tools. The outstanding performance of these milling tools ensures an excellent surface quality that has eliminated the need for a laborious manual grinding process. In addition, the geometric inspections required between the individual work steps are completed automatically in the machine, which has increased precision enormously as there is no need for clamping and declamping. The investment in the Westcam hypermill programming system completes the system. Surface quality is key All these advantages may now be leveraged during production and refreshment of all pressing tools, which is crucial when it comes to the indexable insert production of Boehlerit. At the moment, around 3,500 different pressing tools are in active use at the Kapfenberg plant. Between 100 and 120 tools are made from scratch every year, while several hundred are refurbished and/or repaired. Throughput times for all these processes were reduced massively, while improving the surface quality of the pressing tools and reducing costs at the same time. Boehlerit is also thinking about making the technology available to other businesses as a service feature.

www.boehlerit.com

Maximised precision for inspection

processes as there is no need for

clamping and declamping.