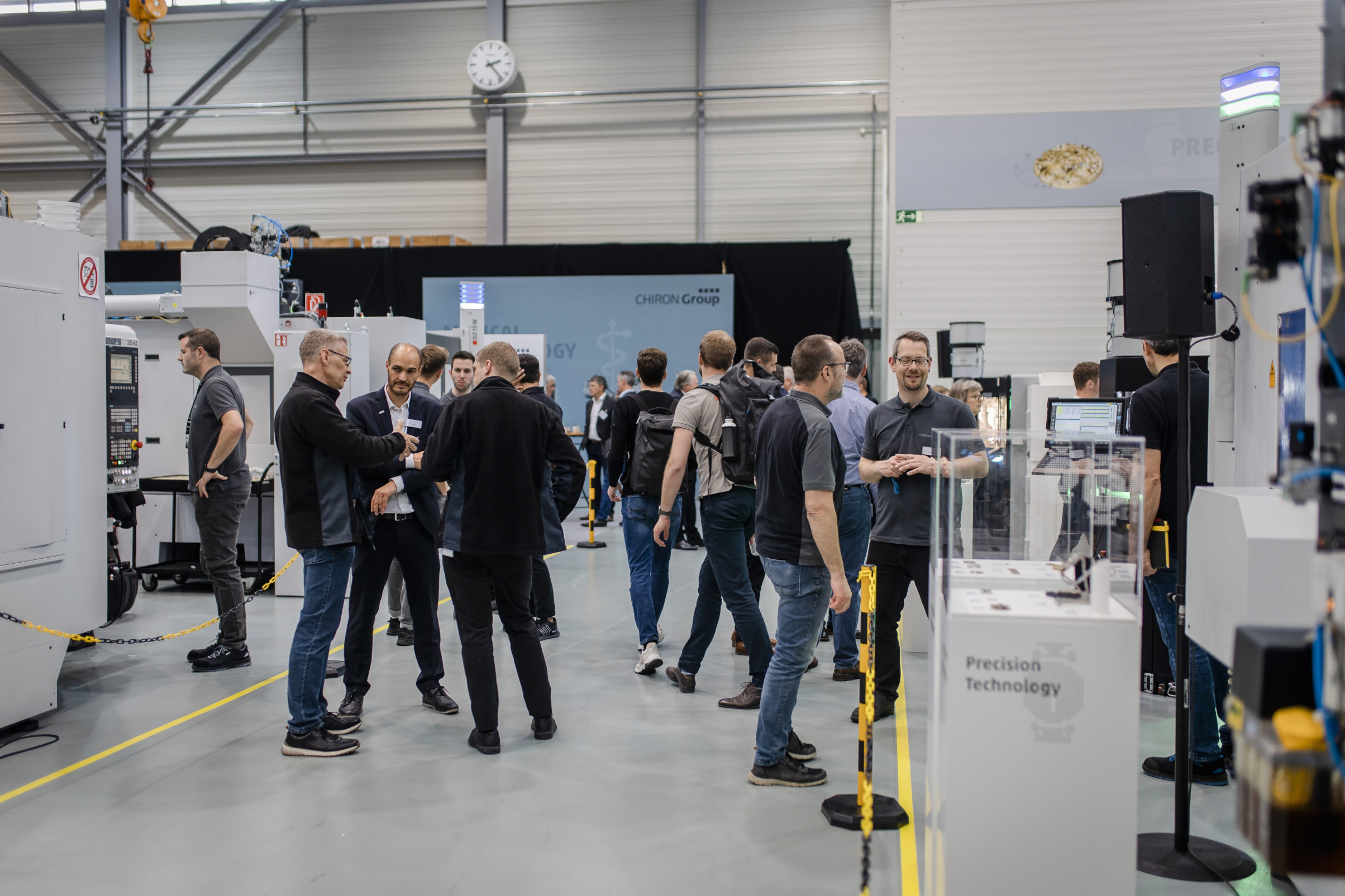

Precision meets automation

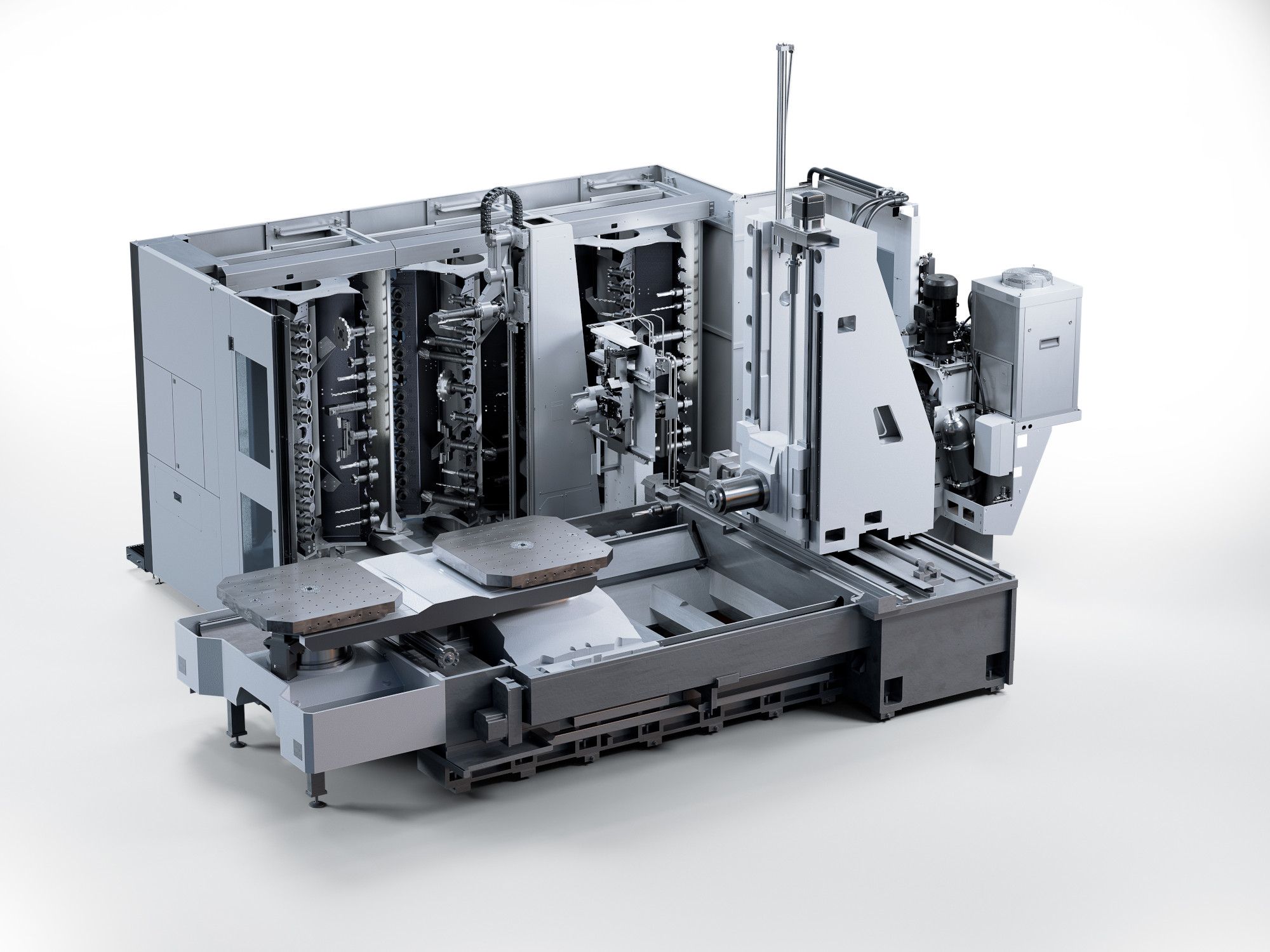

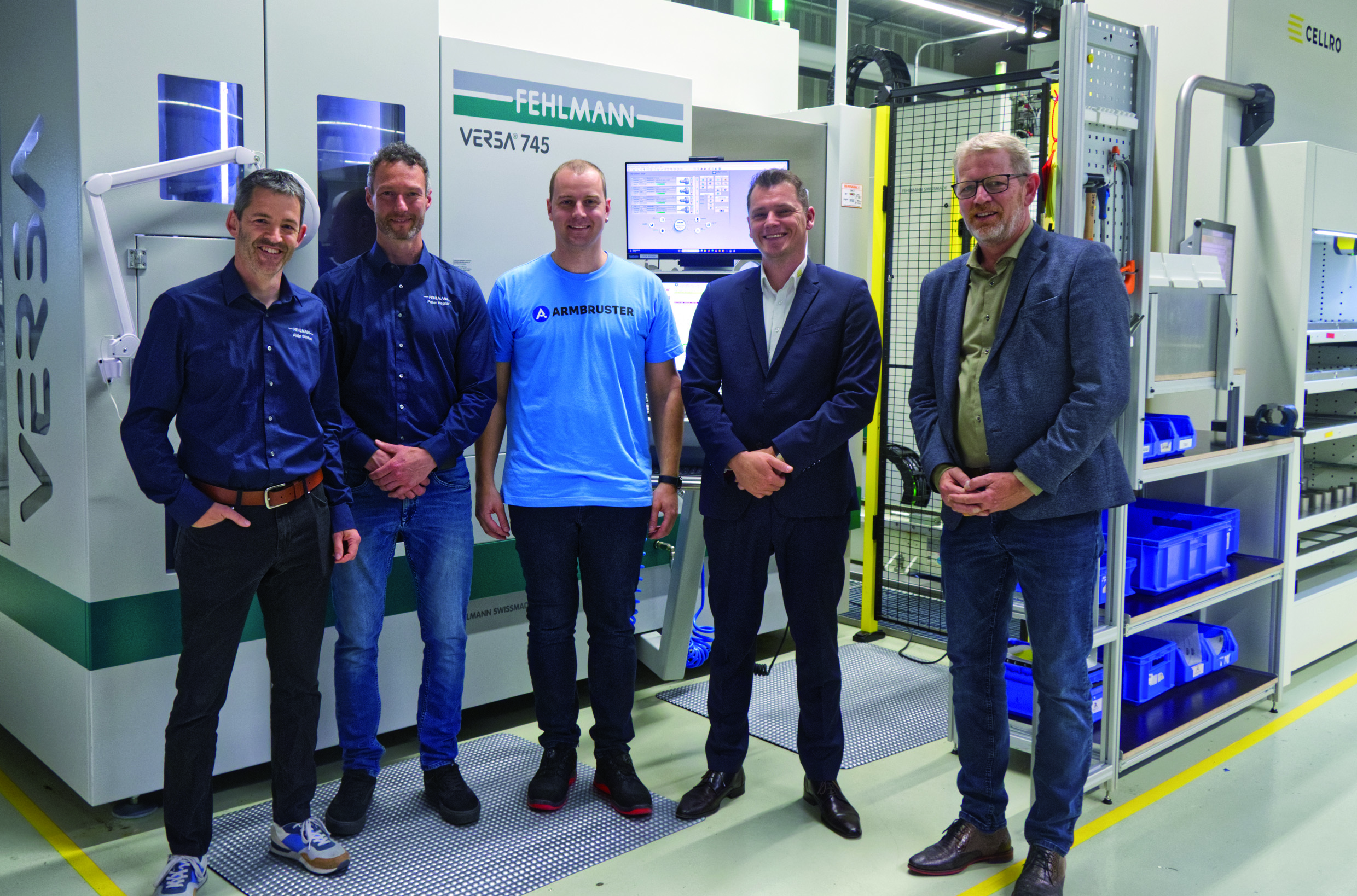

The requirements in medical technology are high – precision in the micrometer range, absolute process reliability, and maximum flexibility are not optional extras, but essentials. For Armbruster GmbH, a specialist in the manufacturing of medical instruments and implants made of stainless steel and titanium, this is a daily reality. In order to continue producing at the highest level in the future, the company invested in a clever combination: two VERSA 745 5-axis machining centers from Fehlmann AG, connected to the flexible automation system Ultimate from Cellro.

Armbruster GmbH, based in Steinach, is a family-run company now in its second generation. For more than three decades, the medium-sized company has focused on manufacturing highly complex components for medical technology, which accounts for around 60 percent of its sales, as well as precision components for mechanical engineering. The manufacturing spectrum ranges from turn-milling, milling, and eroding to metallic 3D printing and numerous surface engineering processes – such as automated cleaning, blasting, streaming, deburring, and polishing – through to final assembly. All processes are integrated into a certified quality management system in accordance with DIN EN ISO 9001 and…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen