Efficient complete machining

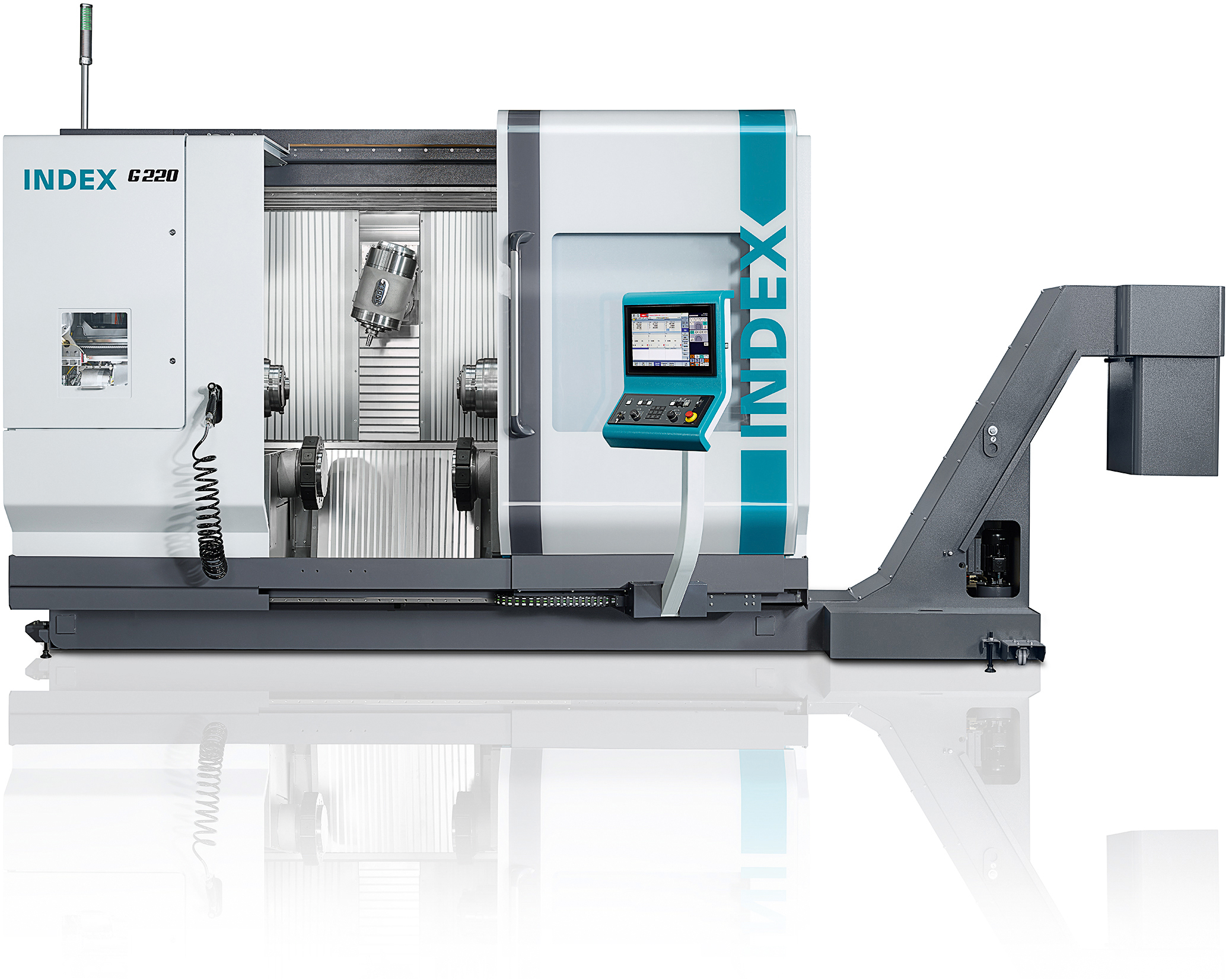

The new generation of the INDEX G220 turn-mill center has arrived and, as of now, is extending the INDEX product range. With a 76 mm spindle clearance, 230 mm chuck diameter and a turning length of 900 mm, this size rounds off the completely redesigned G-series by adding a product of smaller dimensions.

For many metalworkers, complete machining is the process of choice to economically accommodate a higher number of variants, greater performance density with smaller dimensions and increased quality requirements. For INDEX, this was the deciding factor that prompted a complete redesign of the G-series turn-mill centers, taking them to a level deserving the distinction “a class of their own”.

The story starts in 2018, featuring the INDEX G420, which has quickly become an excellent sales success. 2019 saw the larger, more powerful variant INDEX G520 following in its footsteps, while the somewhat smaller G320 launched in 2021. Now, in the spring of 2022, INDEX is introducing the smallest model of these powerful turn-mill centers, the G220.

The success of the new INDEX turn-mill centers can primarily be attributed to the whole concept of the machine design:

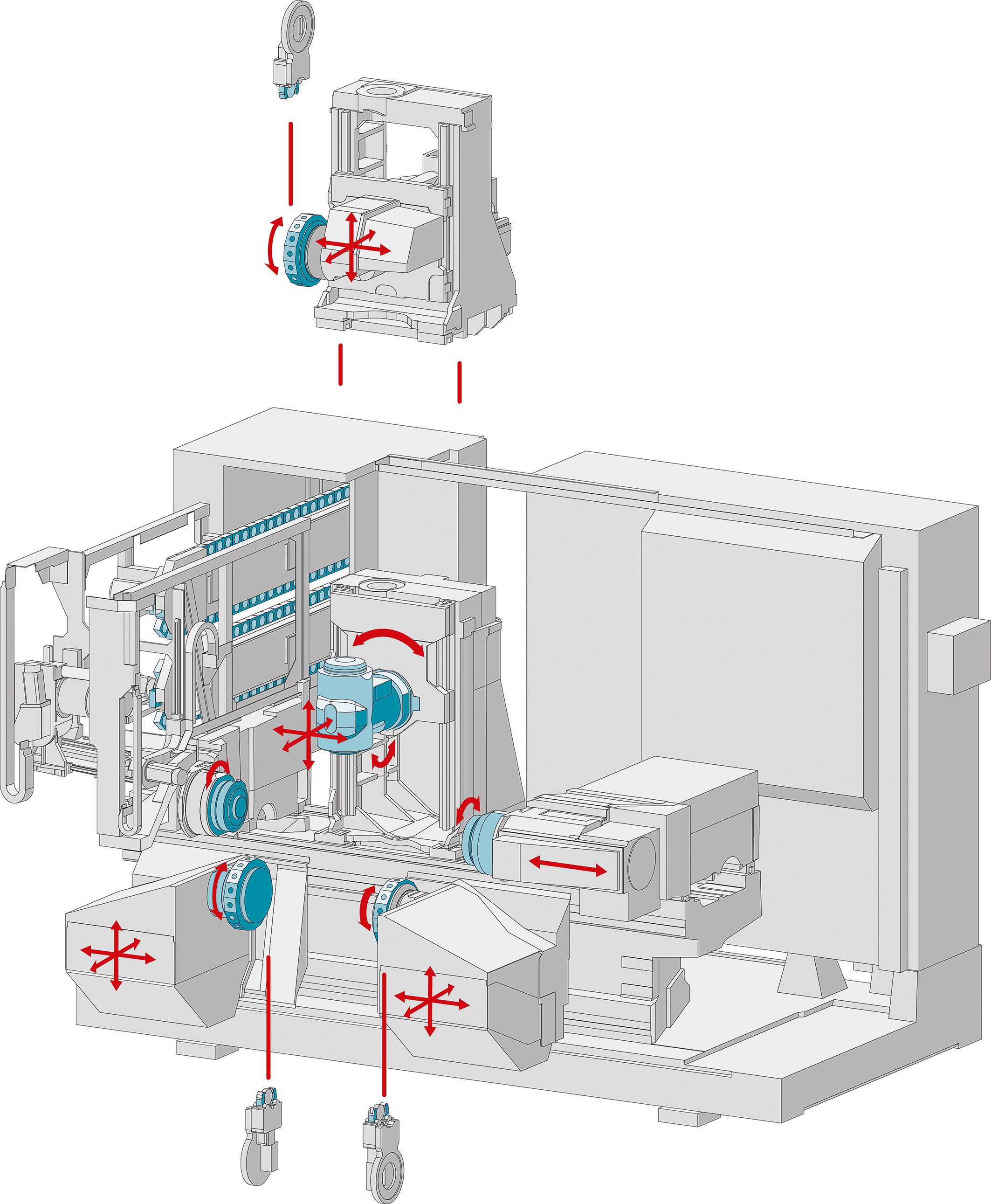

Based on a rigid, vibration-damping machine bed in a mineral cast block design and using generously dimensioned linear guides in the X and Z axes, the new G220 offers ideal stability and damping properties and also dynamic values. All this means that top machining results are guaranteed at the same time as high productivity is achieved.

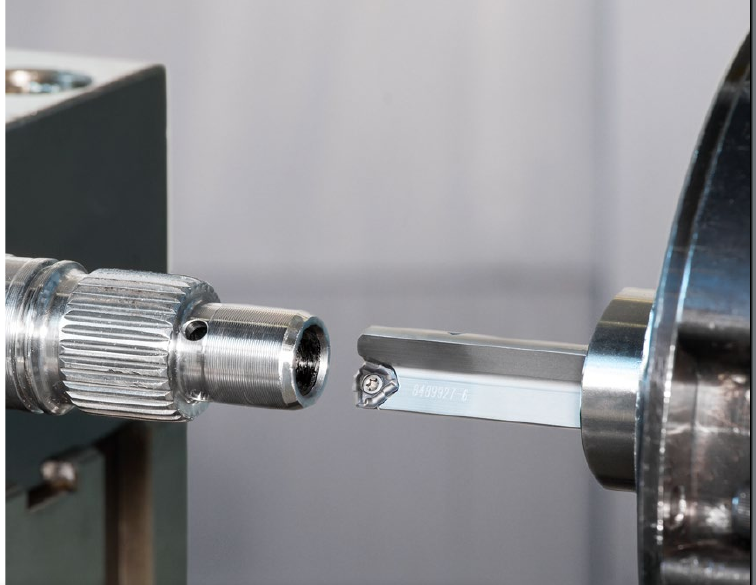

A key element is the Z axis slide with the motorized milling spindle and the hydrodynamically mounted Y/B axis arranged above the axis of rotation. The powerful spindle drive (29 kW, 142 Nm, 6,000 rpm (100% DC)) facilitates a wide range of drilling and milling operations, up to as much as five-axis machining. During machining, the milling spindle operates with a tool magazine with space for up to 139 tools (HSK-T63 or HSK-T40). It stands out particularly because of its enormous ease of setup. Next to the usual setup station located at the front, further access to the two tool chains can be found at the rear of the magazine. This is where the operator can re-tool the one chain while the other one is in use.

The two tool turrets arranged at the bottom are also responsible for efficient machining performance. These are not only able to move in the X and Z directions, but also in the Y direction. Each of their 12 or 15 stations can be continuously equipped with live tools.

The INDEX G220 has a maximum turning length of 900 mm. The two identical work spindles (main and counter spindles) are fluid-cooled and provide a spindle clearance of 76 mm at 6,000 rpm. They are powerful and highly dynamic 29 kW; torque 142 Nm (at 100% DC).

And here comes an important detail:

Thanks to the large working area and the distance between the main and counter spindles, simultaneous machining is possible with the motorized milling spindle and the tool turrets at the main and counter spindles with no risk of collision. The option to lower the tool turrets also makes it possible to avoid and thus defuse situations that could risk collision.

And it goes without saying that INDEX also offers a variety of automation options for the turn-mill center. One such option deserving a particular mention is the new INDEX MBL 76 bar loader. Tailored to match the new machine design and also the new turning spindle diameter, this bar loader stands out in sharp relief because of its excellent damping properties. It is purely electrically powered, which means it is completely hydraulic-free. Its ergonomic and easy-to-set-up structure and, of course, its high precision factor are ready to impress one and all. Last but not least, it achieves faster change times than has been the case up to now with the MBL 65. An integrated gantry-type loader with a double gripper and/or the iXcenter robot cell can be used to deal with flange or shaft-style parts. The control system is a modified Siemens S 840D SL, which can be operated in the user-friendly way via the INDEX iXpanel cockpit solution.

With a turning length of 900 mm, the INDEX G220 is ideal for high-performance turning and milling of components that are of small to medium size.