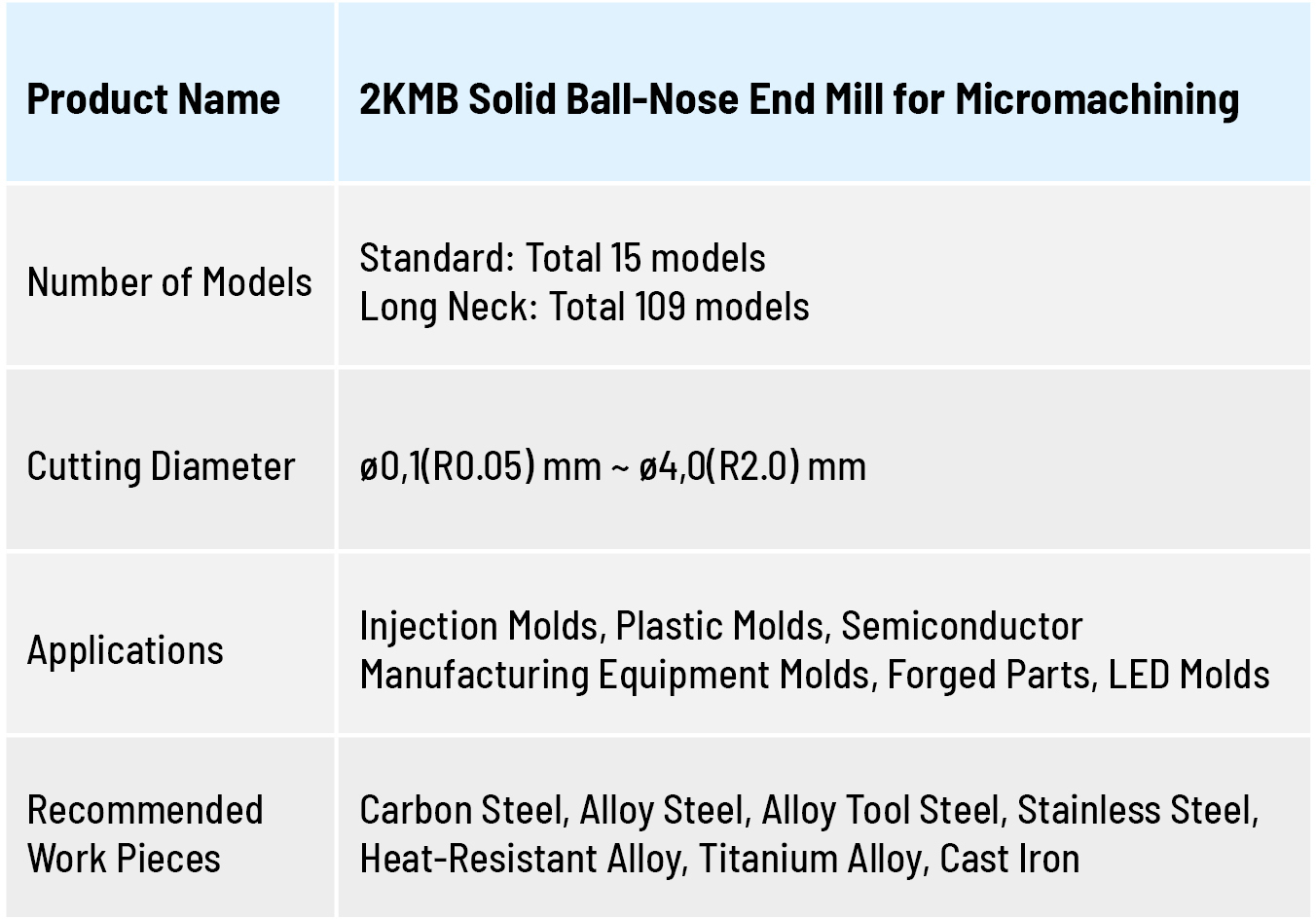

Solid Ball-Nose End Mill “2KMB” for High-Hardness Material Processing, Micromachining

Achieves long life, stable processing with new shape and coating.

Kyocera has announced the launch of its “2KMB” solid ball-nose end mill for high-hardness material processing and micromachining. Used in the fine machining of precision parts and metallic molds, this new solid round tool product is now available globally by Kyocera.

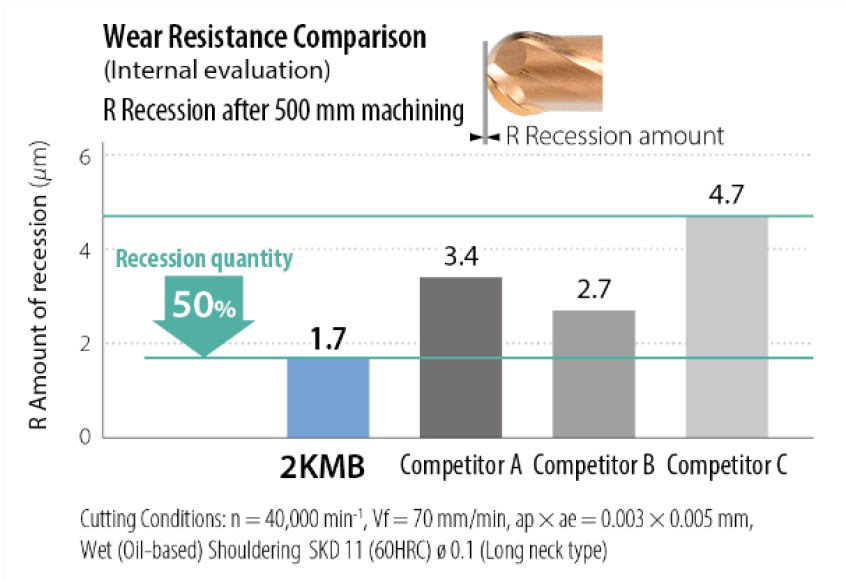

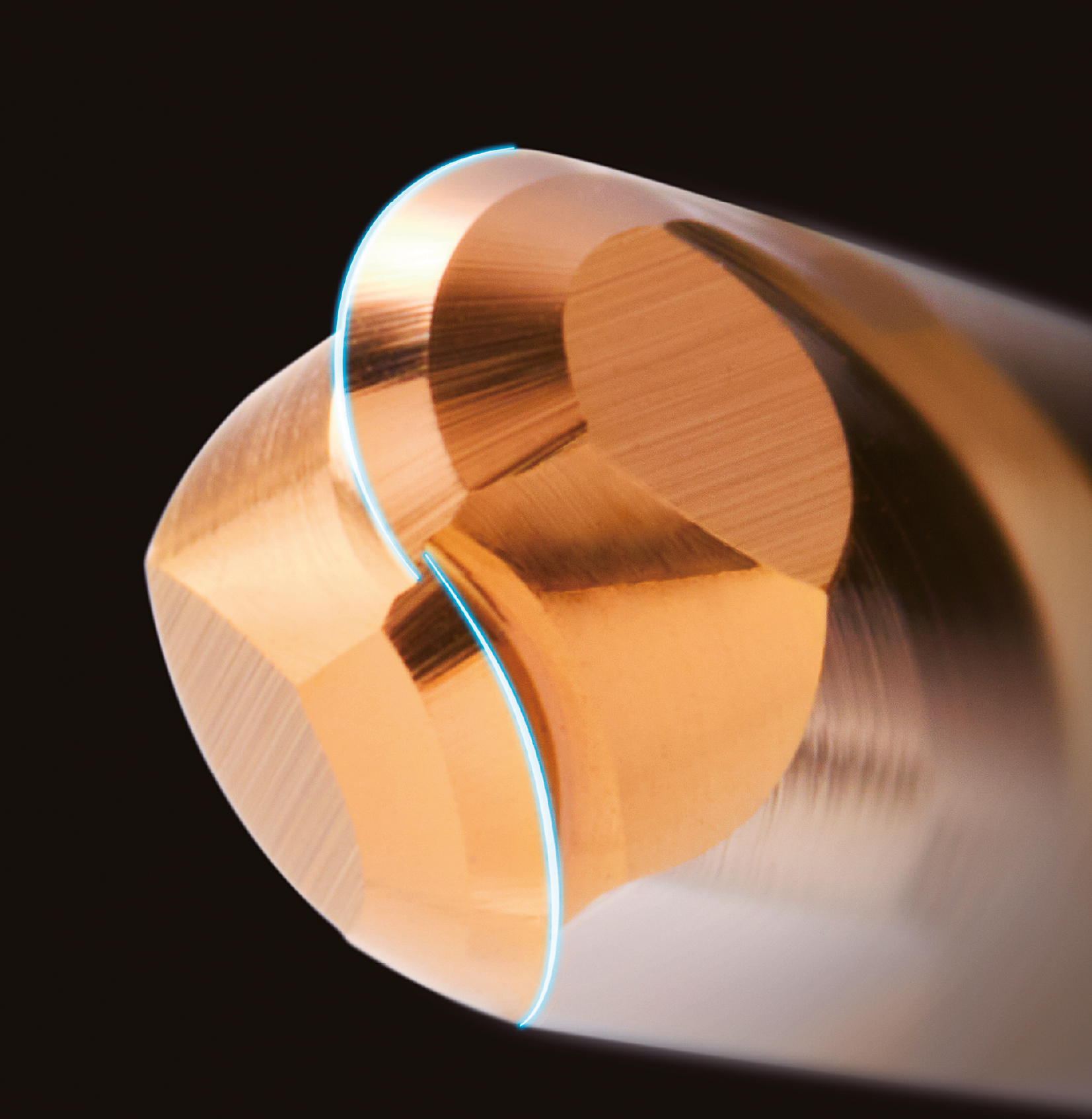

P2KMB is the second product launch in Kyocera’s “K-series” solid tool line, which combines new coating technology with a unique shape for the effective micromachining of various high-hardness materials such as alloy tool steel, stainless steel, and high-speed steel. Kyocera’s new wear-resistant coating, “MEGACOAT®HARD EX”, features a unique two-layer structure to ensure stable processing with high toughness and exceptional chipping resistance. The wear resistance and chipping resistance both contribute to higher quality and longer tool life. In addition, the newly developed, unique S-shaped cutting edge with outstanding sharpness achieves a high-quality surface finish and maintains wear resistance. KYOCERA strives to improve customers’ productivity with products that optimize performance, economy, and functionality.

Solid Ball End Mill “2KMB” (Long Neck).

Features of 2KMB Solid Ball-Nose End Mill for Micromachining

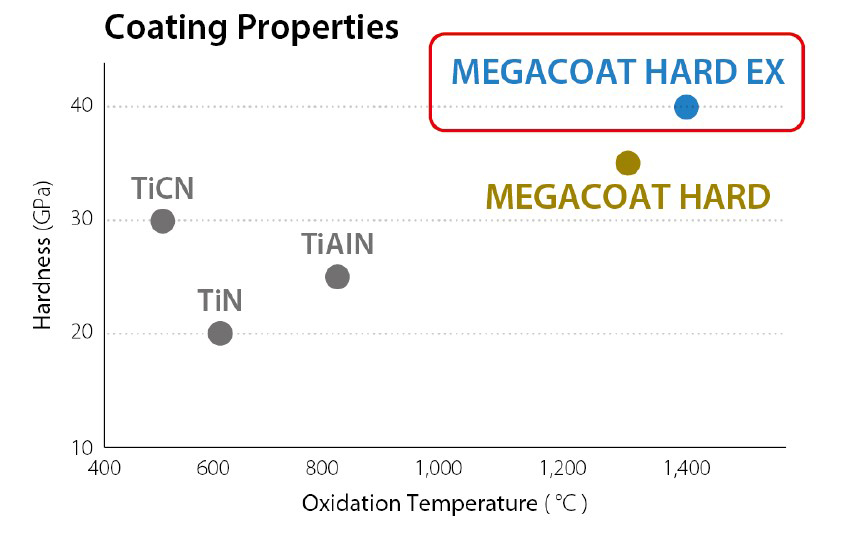

- Proprietary “MEGACOAT ®1 HARD EX” Coating Technology Extends Tool Life

- Achieves stable machining with high toughness and outstanding chipping resistance

- Long tool-life processing is possible due to superior oxidation resistance and wear resistance.

1 “MEGACOAT” is a registered trademark of KYOCERA Corporation.

- Supports quenched hardened steel processing from tempered steel up to 70 HRC.

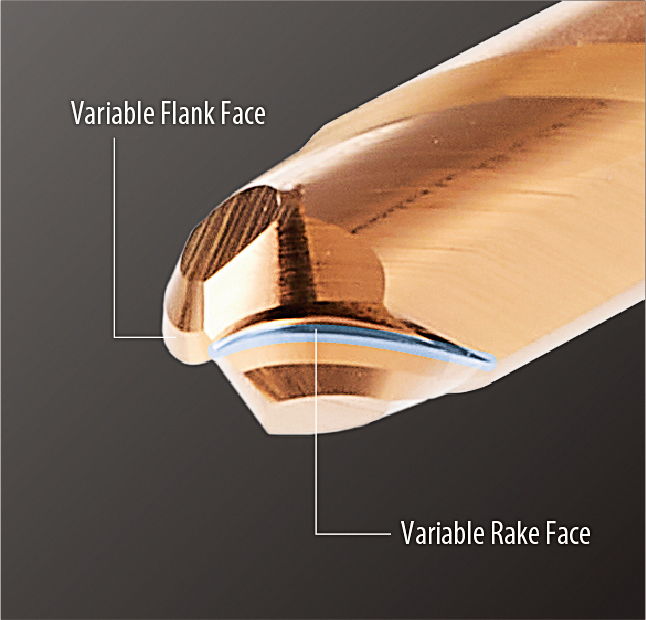

- Unique Cutting-Edge Shape Achieves Superior Sharpness and Wear Resistance

- S-shaped cutting edge achieves high-quality surface finish and high wear resistance.

- Wide core thickness increases tool rigidity, which prevents collapse and ensures stable processing.

- Point cutting (strong back taper) reduces collapse and prevents chattering.

- Unique cutting-edge shape gradually changes rake angle and clearance angle, compatible with high blade edge strength and low resistance.

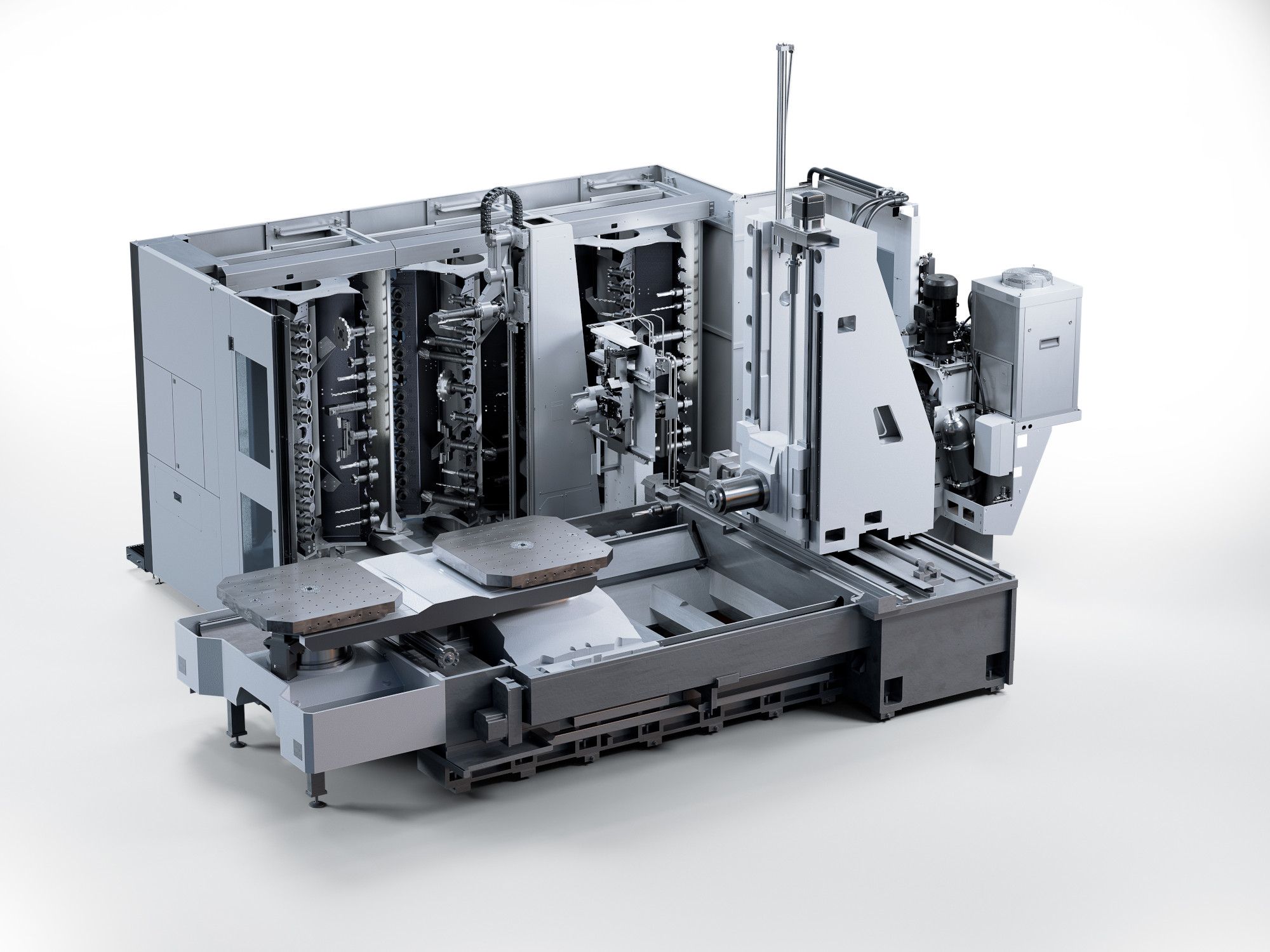

About End Mills

End mills have multiple cutting edges on the outer periphery and bottom. They are used in various industries, such as automotive, aerospace, and industrial machinery, to process grooves and shoulders on metal surfaces by rotating and sliding across the workpiece. To increase productivity, machinists require end mills that can handle a wide range of applications and materials. These high-performance tools must also deliver high-precision machining and long tool life. In addition, ball-nose style end mills are used to cut more complicated, three-dimensional, curved surfaces such as radii and spherical machining applications.

S-shaped Cutting Edge with Unique Shape

Variable Cutting Edge Shape