From “Plug & Pray” to “Plug & Play”

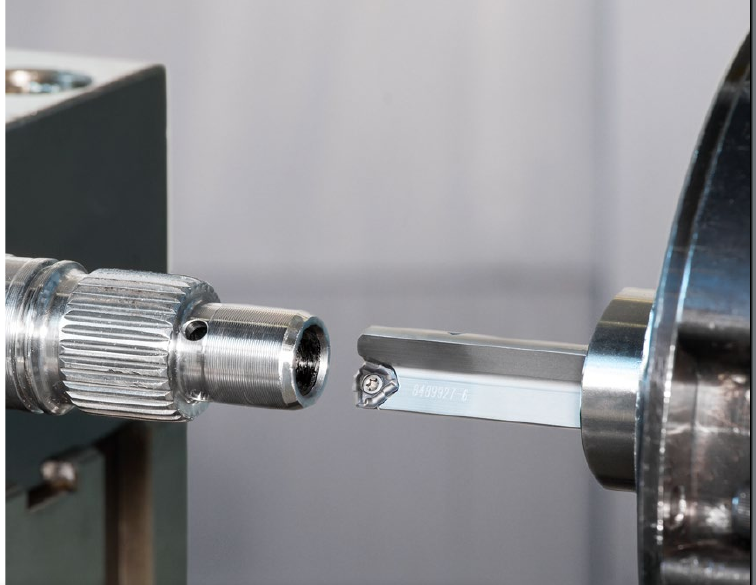

Gear skiving used to be a gear cutting method that was difficult to control due to its complex kinematics, but it now offers a genuine alternative to shaping or broaching. The synergy between machines, tools and processes provided by Liebherr-Verzahntechnik GmbH’s Skiving3 technology package makes it possible to efficiently and flexibly machine an extremely wide variety of workpieces, including in small batch sizes. Skiving3 therefore crucially boosts productivity, quality and cost-effectiveness levels not just in series production, but in contract gear manufacturing as well.

Gear skiving is a continuous rotary gear cutting method in which the workpiece and tool are arranged at a cross-axis angle. Not only does this provide higher degrees of freedom when machining, it is also productive and cost-effective. Skiving is suitable for an extremely wide variety of workpieces – for large and small gears, external and internal gears, and workpieces with interference contours. However, skiving’s complex process kinematics impeded its popularity for some time. Haider Arroum is the Head of Sales for gear cutting tools at Liebherr-Verzahntechnik GmbH and recalls that “gear skiving used to be a tedious and repetitive…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen