Clamping and automation solutions for all production needs

Später lesen

Clamping

Von

Maxime Mader

veröffentlicht am

29/08/2025

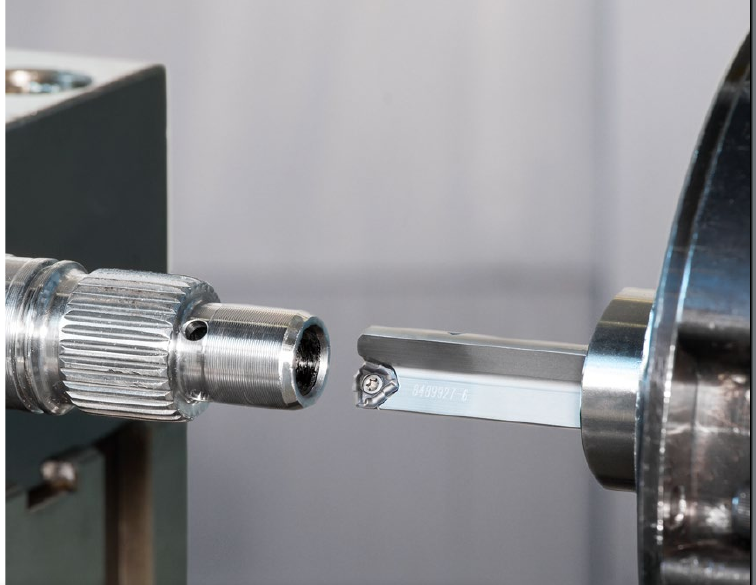

The future of metalworking is flexible, precise, and automated. At EMO Hannover 2025, SCHUNK will demonstrate how flexible clamping devices, modular automation concepts, and global engineering expertise help companies make their processes efficient and future-proof.

How can companies future-proof their processes in times of global uncertainty, increasing competitive and cost pressure, and a shortage of skilled workers? This question is more relevant than ever for the metalworking industry. EMO Hannover, the world’s leading trade show for production technology, provides the answers. At SCHUNK, visitors can expect practical manufacturing modules that make in-machine part handling and machining easier, more flexible, and more resource-efficient. Efficient machine tool automation Automated loading and unloading are key drivers for increasing productivity and efficiency in the manufacturing process. But which automation solution fits which production environment? The application specialist provides guidance…Abonnenteninhalt

Abonnieren Sie, um auf alle Inhalte

von Werkzeug Technik zuzugreifen

Bereits abonniert ? Einloggen

SCHUNK GMBH & CO. KG

http://www.schunk.de

Über uns cutting-tools

INDEX-Werke GmbH & Co. KG Hahn & Tessky

Experten präsentieren effiziente Fertigung

Clamping

actualites

SUMITOMO ELECTRIC HARTMETALL GMBH

Bruchzäher und verschleißfester PKD-Schneidstoff

Clamping

actualites

Meistgelesen

Lesen Sie auch

3D3D-Druck5-Achs-Schleifmaschinen5-AchsenAdditive Manufacturing