Innovative Solutions for Renewable Energy

Under the banner “Innovate manufacturing,” industry leaders will once again come together at the EMO trade show in Hanover from 18 to 23 September 2023. The EMO is the world’s leading trade show for production technology, providing full-spectrum coverage of the sector. Systems supplier KLINGELNBERG will also be represented with a booth, but in a new hall this time around. Trade show visitors can look forward to exciting and interesting discussions with Klingelnberg’s team of experts in Hall 11, Booth F51. In addition to numerous machine demonstrations, Klingelnberg will even be offering a dedicated lecture series directly at its booth.

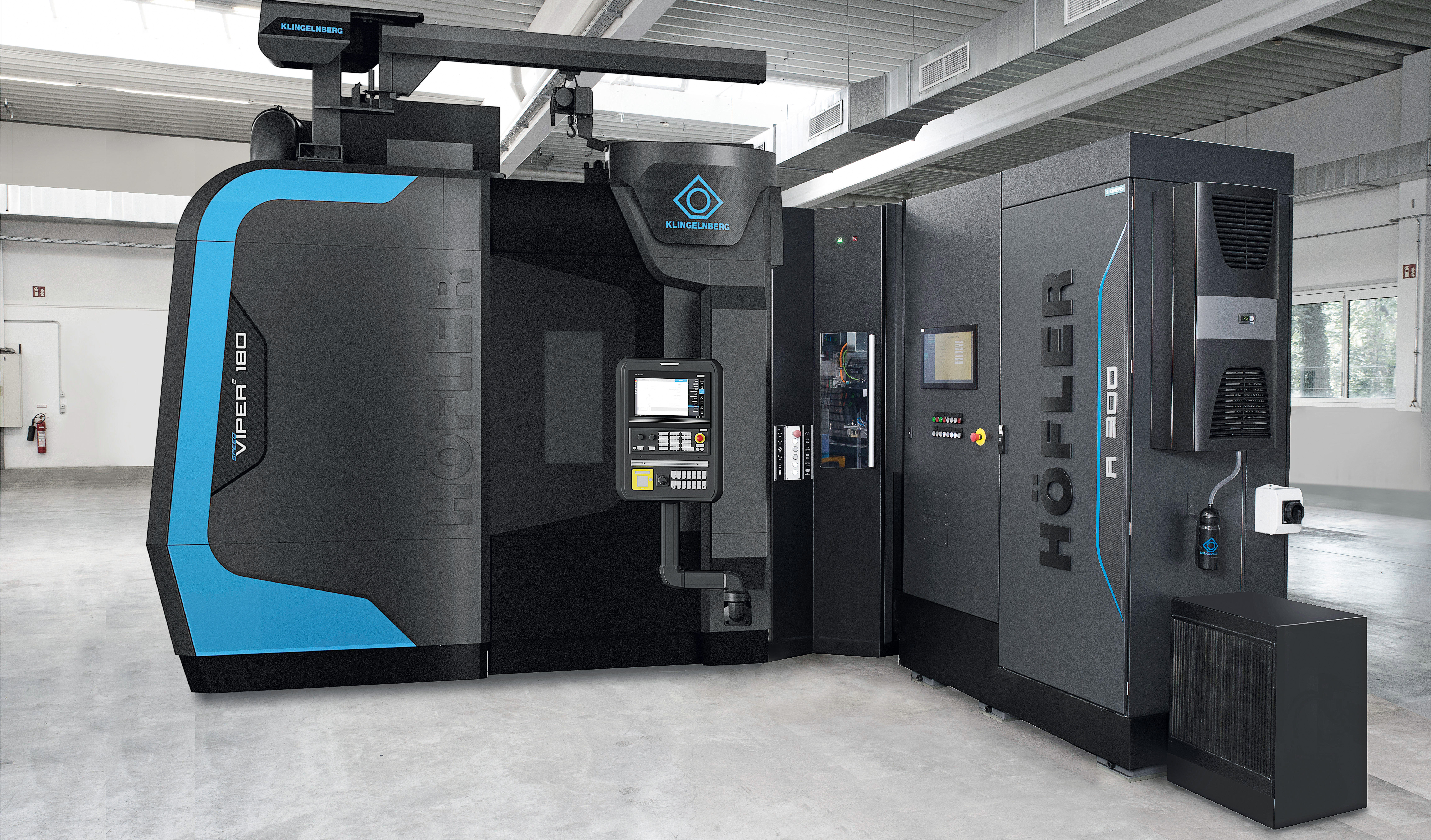

In recent years, Klingelnberg has worked continuously with many of its customers to analyze the challenges presented by renewable energies, such as electromobility and wind energy, and incorporate them into the company’s development process. The high standards in regard to noise behavior of gears in electric cars are a key aspect that has come to light based on numerous discussions. This has led to new products and advances in existing products that are designed to manufacture application-specific, high-quality gears on a cost-effective basis, now and in the future. The highest profile addition to the Klingelnberg portfolio is the Höfler Roll Testing Machine R 300 for torsional acceleration testing of gears. At EMO Hannover, Klingelnberg will also be exhibiting the Höfler Cylindrical Gear Grinding Machine Speed Viper and the series P 152, P 40, and P 26 precision measuring centers.

Höfler Cylindrical Gear Roll Testing Machine R 300 – The Gear Noise Finder

The metrology on the Höfler Cylindrical Gear Roll Testing Machine R 300 provides a reliable way to determine the root causes of gearbox noise. Due to the short measuring time, it can be easily integrated into any manufacturing process and enables 100 % quality control of the gears produced. The R 300 is designed for all roll testing processes that are relevant for evaluating the running behavior and noise behavior of gears. These include the single-flank test, the structure-borne noise test and torsional acceleration test, and the double flank test. Depending on its equipment, the R 300 enables testing of gears and shafts, a particularly important factor for components from an electric vehicle drivetrain system (eDrive). For testing the eDrive intermediate shaft, Klingelnberg will demonstrate a process for roll testing both gears on the shaft in one test cycle. This saves time for a second loading and unloading and for re-tooling the machine, and reduces test costs.

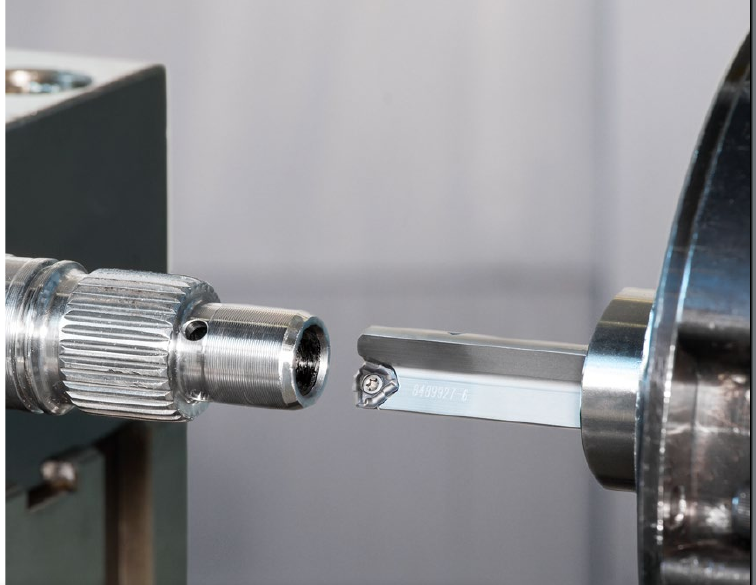

P 152 Control Unit.

Speed Viper and R 300 Combined into one Production Cell

A 100% quality control of the gears can be carried out either as an incoming inspection for assembly or immediately after hard finishing of the gear in production. The advantage of the latter option is that only OK parts are passed on to the next process step, thus preventing any rejects from undergoing the finishing process. The Klingelnberg production cell – consisting of the Höfler Cylindrical Gear Grinding Machine Speed Viper, the CompactLoader and the integrated Höfler Cylindrical Gear Roll Testing Machine R 300 – is ideally suited for this purpose. The production cell can be equipped with all machine models in the Speed Viper series – from the Speed Viper 80² (dual spindle) to the Speed Viper 300. The Klingelnberg production cell is the solution for the manufacture and 100 % quality testing of high-precision gears for the electric drive train.

What’s more, the R 300 is networked with Klingelnberg’s GearEngine®, making it possible to use roll testing data for production evaluation and tolerance management. With the optionally available R 300 production monitor, users always have a documented overview of the current key quality indicators in their production.

P 152 – The Solution for Medium-Sized Gears

The increasing cost pressure on large components for wind power requires new technologies that will enable proven principles for high-volume and mass production of smaller components to be transferred over to large components. The newly developed Klingelnberg Precision Measuring Center P 152 closes the gap in the portfolio between the mid-sized and the large precision measuring center model series.

The latest addition to the family is capable of measuring components with a maximum outside diameter of 1 520 mm and workpiece weights up to 8 000 kg with the usual measurement precision. Despite this heavy workpiece weight, no special foundation is required. Klingelnberg has succeeded in scaling the technology concept of the small and mid-sized series to the larger component dimensions. The inherently rigid machine bed with its 3-point support plays a key role here. The bed design and floor support are so cleverly designed that even when loaded with heavy workpiece weights, the angular position of the individual machine axes to each other does not change significantly. The machine bed’s 3-point support enables the integration of an active vibration platform into the machine bed. This means that even the low-frequency oscillations from the shop floor can be safely absorbed without the use of a vibration-isolating foundation. Consequently, all changes visible in the measurement results can actually be attributed to the component and are not induced by the ambient conditions.

Hybrid Metrology.

P 40 – Universal All-Rounder for Reducing Measurement Times in Series Measurement using a Hybrid Solution

The introduction of hybrid metrology with optical pitch measurement has significantly reduced measurement times. It is now possible to perform optical pitch measurement on almost all surfaces using the white light sensor technology (HISPEED OPTOSCAN) developed by Klingelnberg and partners, along with other innovative measuring strategies. Two other processes for reliably measuring single pitch deviations are also available.

All Klingelnberg Precision Measuring Centers in the P 26 to P 65 series can be optionally retrofitted with the optical sensor (HISPEED OPTOSCAN). For new machines, the “Ready for Optic” option is also available, providing a factory-installed setup for subsequent retrofitting. Through the systematic use of the standardized Gear Data Exchange (GDE) interface when importing and exporting data and measurement results, Klingelnberg has set a higher standard in Metrology 4.0 in the area of measurement results diagnostics and networking of production machines and metrology – a system it calls the Closed Loop.

P 26 – For a Wide Range of Applications Covering All Aspects of Gear and Geometry Measurement

Compact and tailored to the needs of the automotive industry, this all-rounder of a precision measuring center has been extremely popular with customers for over 25 years. Its 25-year success story was built on a foundation of new measurement and evaluation methods, the implementation of innovative measuring systems, and uniform quality and reliability. It is because of their accuracy and reliability that Klingelnberg Precision Measuring Centers are used as a reference around the world, not just by countless customers, but also by renowned metrology institutes.

SmartTooling Becomes SmartFactory

SmartTooling is now SmartFactory, enabling the management of all assets in production. SmartFactory gives users an overview of sites and consumption data at all times, and not just for Klingelnberg machines. Mobile devices support a wide range of operations with extreme ease. For Klingelnberg processing machines in particular, Klingelnberg offers new evaluation and input options with Smart Process Control, enabling optimal and efficient control of the production process.

Gear Campus: Experience Exciting, Exclusive Presentations Live at the Trade Show Booth

For the first time, Klingelnberg will offer interested trade show visitors live presentations in a short-seminar format on the subjects of aviation, wind energy, and automotive applications. Digital solutions for smart production will also be part of the lecture series. At scheduled times, the team of experts will give 20-minute presentations followed by a discussion in German and English directly at the trade show booth in the company’s own Gear Campus. Pre-registration is not required.

Klingelnberg Precision Measuring Center P 152 for medium-sized gears.