The articulated cube by Tommy: a fusion of art and technology

This cubic object with its complex interlocking geometrical forms is a most impressive demonstration of technical skill. Here’s the story.

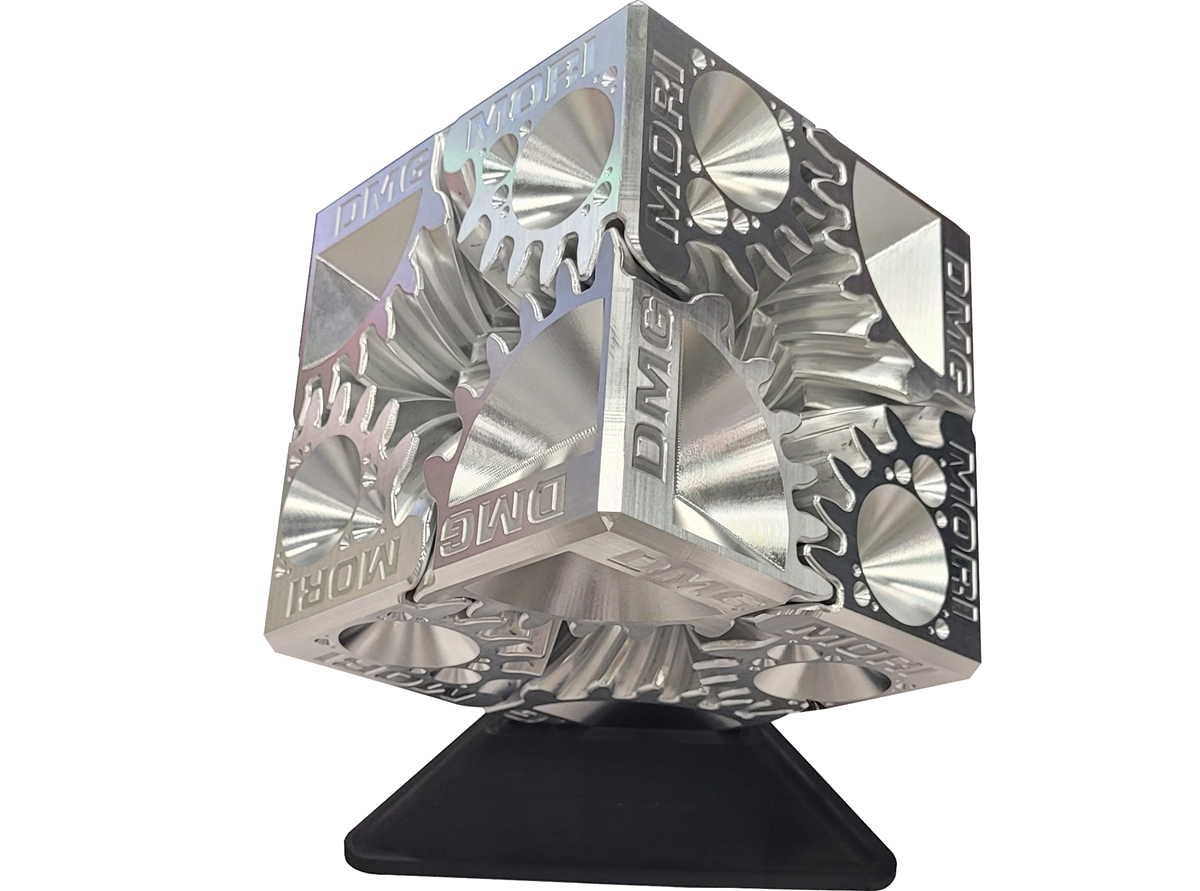

Our curiosity was raised by a video posted on the LinkedIn professional social media showing a strange object on display at the DMG Mori Canada open day in Mississauga (Ontario). The designer: Tommy Guimond, 45 years, applications technician for the German-Japanese manufacturer. The object in question is a metal cube which turns on its own axis and opens as it rotates like the petals of a flower, splitting up into eight smaller cubes.

This articulated object was made to demonstrate the abilities of its designer, Tommy Guimond, an individual who is deeply passionate about machining and exactly this type of challenge. But it was also made to demonstrate the precision of DMG Mori machine-tools.

CUBE-2: Tommy Guimond at his home in Saint-Jean-sur-Richelieu (Quebec) holding the 3D printed prototype for his cube.

The idea behind the design of the cube comes from a film: Hellraiser. The film concerns a number of infernal creatures known as Cenobites which can travel between dimensions using a “cube” which is in fact a kind of sophisticated mechanical puzzle. Tommy Guimond also remembers seeing a similar object on a 3D printing fan group.

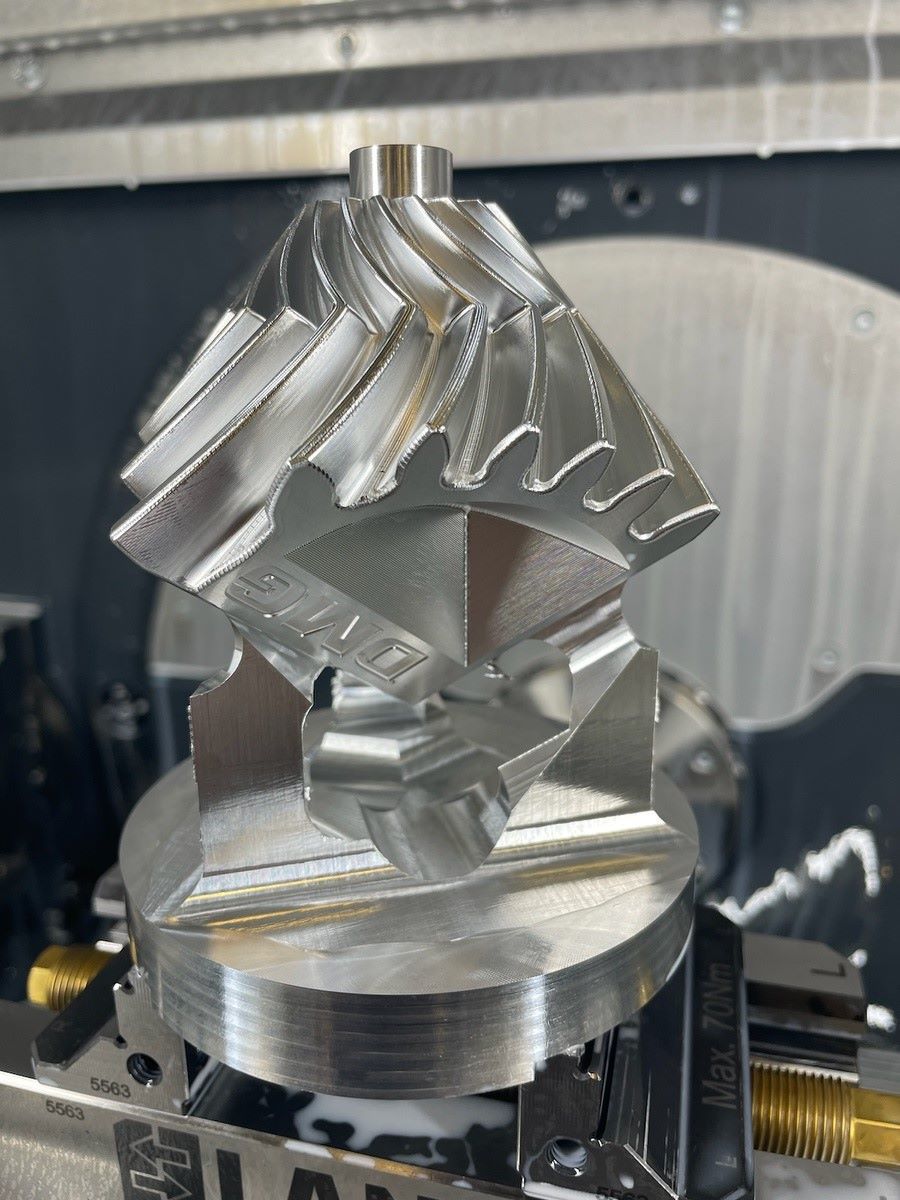

It is exactly the kind of object, with complex interlocking geometrical forms, that you can often see on the stands of additive manufacturing professionals, used by them to show off the potentials of their technology. But in this case, this object has been produced using subtractive manufacturing using a 3rd generation DMG Mori DMU50 milling machine fitted with a Heidenhain TNC640 controller. And what’s more: “I took it even further by adding a double-helix mechanism which is very stable but, on the other hand, very difficult to generate.”

CUBE-3: The steel ball bearing which animates the cube.

He told us that he built it from scratch during his time off and that it took “about three weeks” to make the cube, “including the first two versions which I didn’t really like”. It took two weeks to program the Esprit Edge CAM software, but this also included the time it took to machine the prototype. Another prototype was produced using his PLA filament 3D printer.

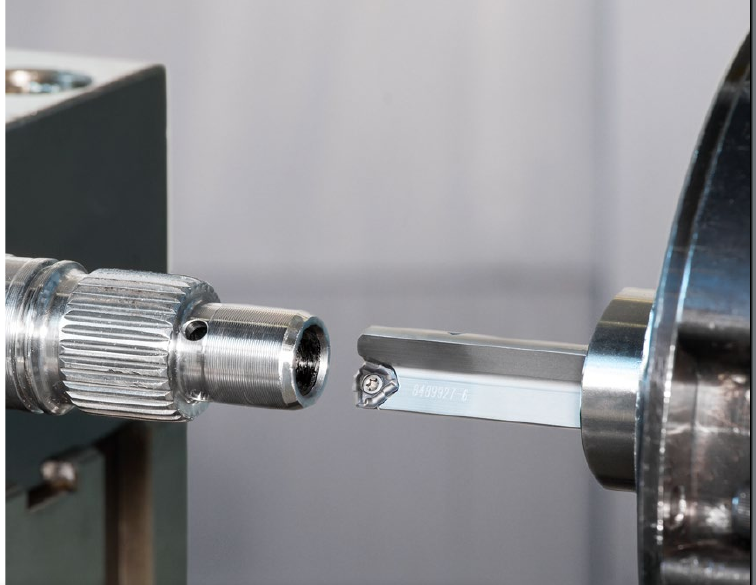

Tommy Guimond started with a lump of aluminium. This was because, as he told Machines Production, “the assembly method required a non-magnetic material”. And he also told us: “I would have liked to make it from titanium but the costs would have been so much more and I would not have had enough time since it is slower to work.”

The double-helix mechanism was no mean feat. Without revealing any manufacturing secrets, the machinist from Quebec could only tell us that he needed to “push the limits of his ‘geometrical’ and ‘mathematical’ imagination. The DMG Mori Canada applications technician used Kennametal tools from his supplier, Ron Hansen, who “graciously donated the tools and tool-holders necessary for the project”. On the cube you can see that the names DMG and Mori have been engraved separately such that they join together when the cube is closed, representing the union of the two manufacturers. This is why it has been named the “Synergy Cube”.

Once the eight smaller cubes had been machined, it was time to assemble. “Each part has a hollow at its tip where a powerful neodymium magnet is be fitted. The whole assembly then sits on a good-sized steel ball bearing. The assembly ensures is such that the whole thing dislocates if someone gets a finger caught in it.”

CUBE-4: The double-helix mechanism machined on a DMG Mori DMU50 milling machine.